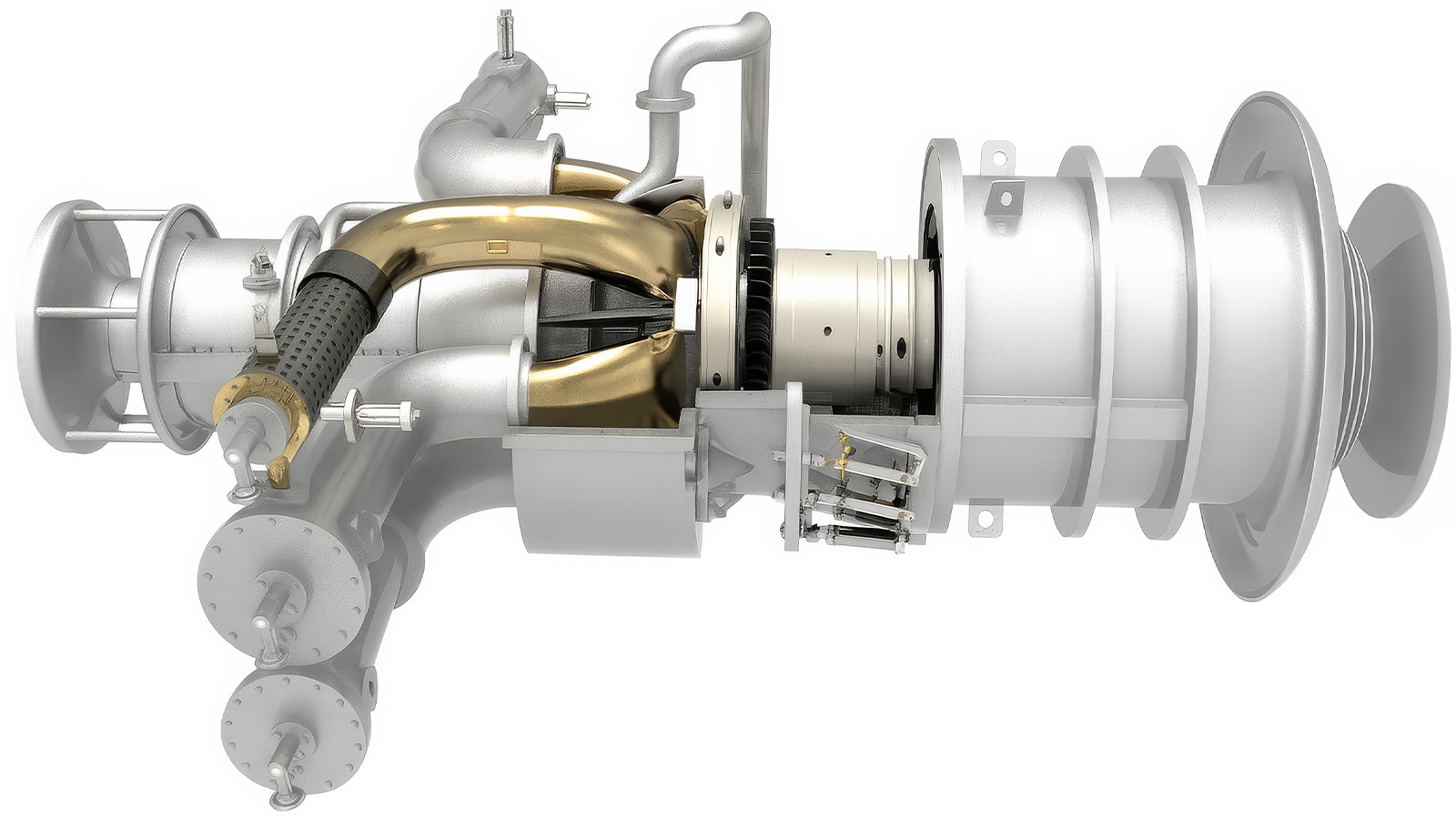

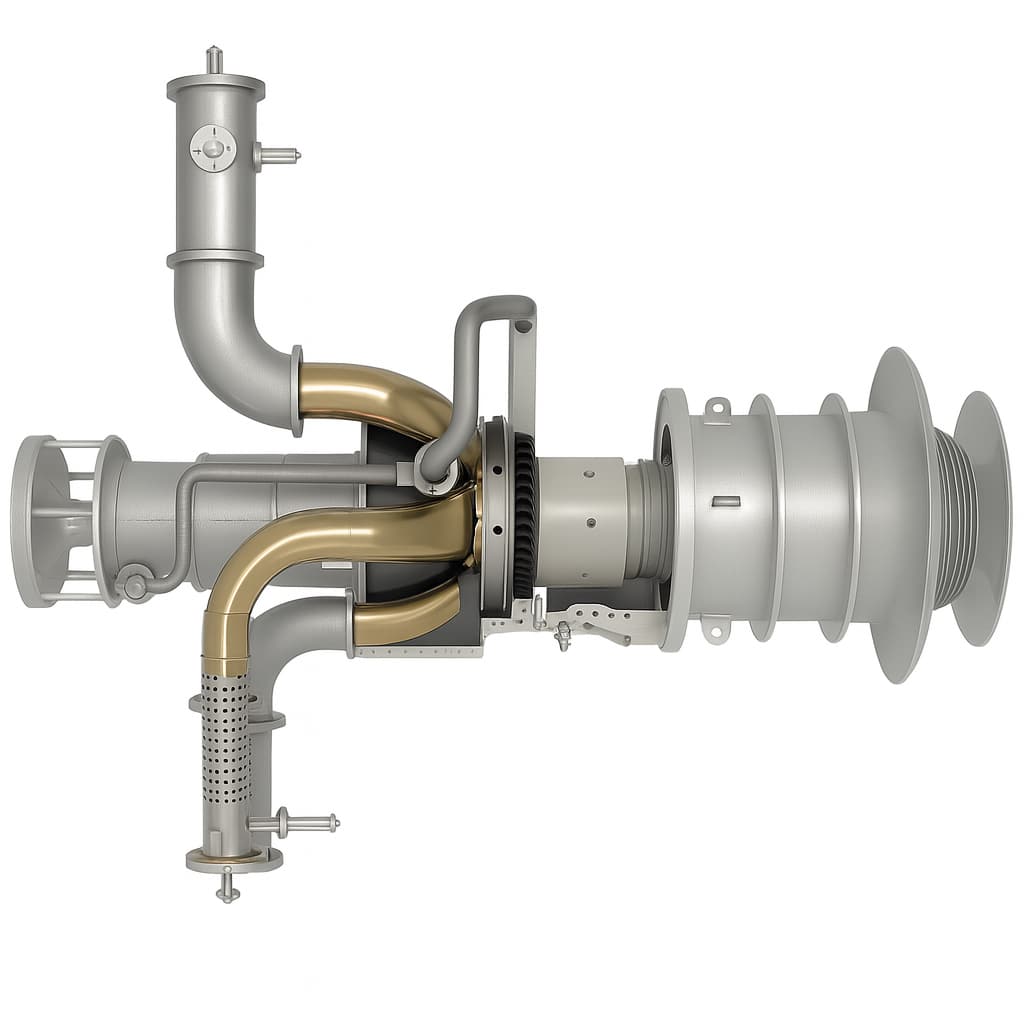

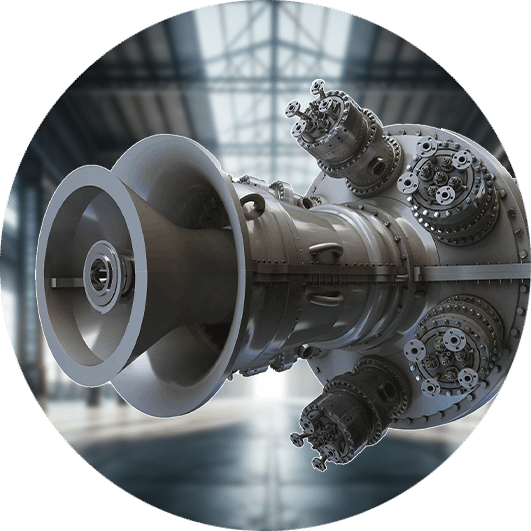

GE Frame 3 Gas Turbine Repair Services

Legacy Turbine Support You Can Trust—Expert Repairs for GE Frame 3 Units

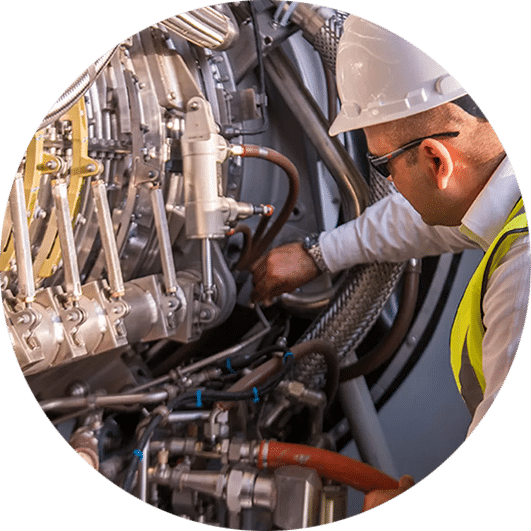

Allied Power Group specializes in the maintenance and restoration of GE Frame 3 gas turbines, providing dependable repair solutions for one of the most widely deployed legacy turbine platforms. Whether you're managing an aging asset or preparing for a scheduled inspection, our team offers OEM-alternative services that extend equipment life, improve performance, and lower total cost of ownership. With deep experience across GE Frame units and integrated field/shop capabilities, we help you get more from your Frame 3 investment—without sacrificing reliability.1,300+

GE Bucket Repairs

900+

GE Nozzles Repaired

800+

GE Shroud Blocks Repaired

900+

GE Combustion Liners Repaired