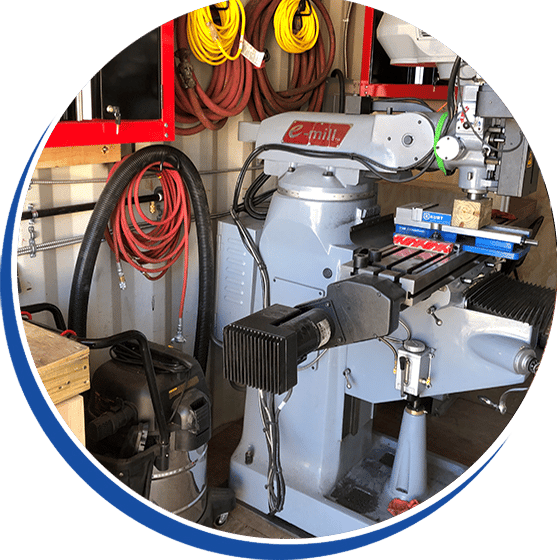

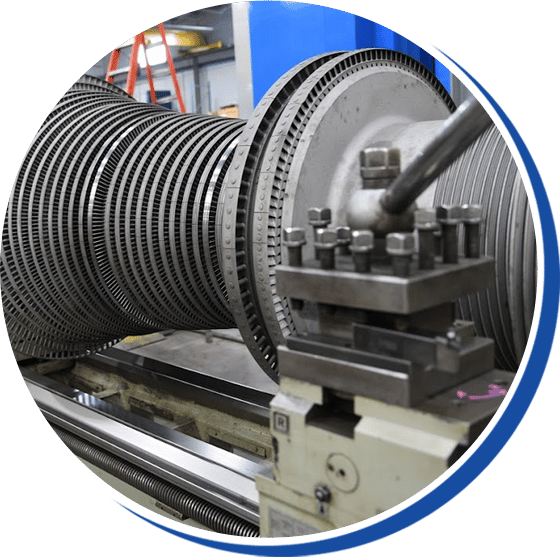

APG’s Gas & Steam Field Services group offers complete turnkey support, ensuring your major outages and other mission critical maintenance functions are managed and completed efficiently while minimizing downtime. We specialize in full-service inspection and repair of a wide variety of both advanced technological and mature frame gas and steam turbine components

at power plants. Our field service support solutions for power plant maintenance are second to none in the region. All thanks to the highest level of international compliance. We work with the likes of GE and Siemens that’s a testament to our world-class thermal power plant operation and maintenance field services.

APG can be the field service provider of your steam/gas turbine power plants around the world. Share your power plant project service needs with our field service consultant and we will work out the best solution for your specific needs.