Cut Costs On Your Largest Expense

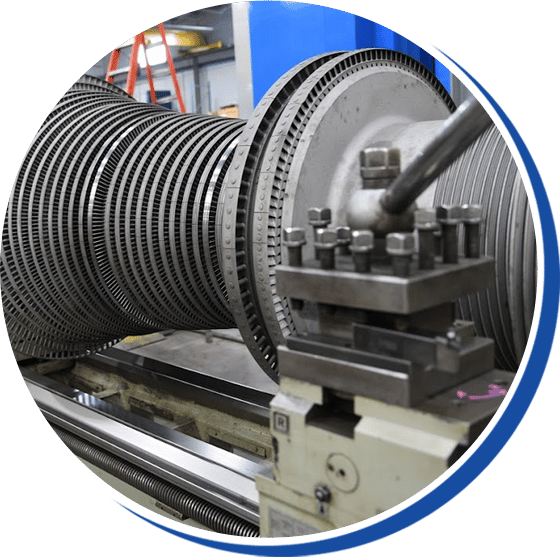

Improving the heat rate of your gas turbine is an easy way to save money on your plant’s largest O&M Expense, Fuel. Whether it is cloth side seals, brush seals, or honeycomb seals, APG can help you in determining the appropriate sealing technologies to improve your unit’s heat rate.

Our certified technicians provide field services, thus saving your valuable business time and money in shipping the parts to our Houston facility. We have preowned inventory to replace old turbine seals while engineering new ones in compliance with the highest quality standards.

All thanks to our advanced diagnostics and engineering technology, APG guarantees world-class sealing technology solutions that accurately work for various turbine applications.

Stationary Parts Sealing

Shaft Sealing

Seal Clearance Reductions

Stationary Parts Sealing

Liquid or gas leakage can significantly reduce turbine efficiency. That’s where our stationary parts sealing comes into the picture. We use mechanical seals (O-rings, gaskets, and diaphragms) to contain the flowing liquid within the housing compartment as a rotating shaft enters. Ensuring the fluid is contained inside and contaminants like dust and debris remain outside, our sealing solutions help preserve the stationary parts of the turbine.

Shaft Sealing

Gas turbines operate at high speeds and temperatures, leading to gas or oil leaks if the shaft is not correctly sealed. Our effective shaft-sealing solutions prevent the leakage of lubricants, gases, or fluids, ensuring that the turbine operates efficiently and safely while reducing toxic gas emissions and improving the gas equipment's lifespan.

Seal Clearance Reductions

APG uses labyrinth seals and other uniquely designed clearance seals to protect turbines from leakages while improving performance and efficiency. Our engineers work towards reducing seal clearances while adding to the availability and reliability of the turbines. Ensuring that contaminants do not affect operational efficiency and maximize savings. We also use brush seals for the most common GE Frame 9, 7, 6, and 5 models and the Westinghouse 501 series.

How Do Shaft Seals Benefit Gas Turbines?

APG provides comprehensive shaft sealing solutions for GE, Siemens, and other global brands.

Our extensive knowledge and experience help us determine the best seal for industrial gas turbines of different models and makes.

- Reduced air ingress: It helps to prevent air from entering the steam turbine, which can decrease its efficiency.

- Increased Efficiency: It helps maintain the optimal operating conditions of the gas turbine, leading to improved efficiency, performance, and cost savings.

- Extended Equipment Life: It helps extend the service life of gas turbines by reducing wear and tear on the equipment caused by friction and leaks.

- Environmental Protection: It prevents the release of harmful gases or fluids into the environment, thus contributing to the health of the surrounding ecosystem.

- Safety: A well-designed shaft sealing system helps to improve the safety of the entire industrial gas turbine system. This can protect both employees and the equipment itself.

Our engineers will work with clients to determine the best sealing solution for your project. From selecting to installing the seal and beyond, we can help improve the heat rate of the unit.

Frequently Asked Questions

- Gaskets

- O-rings

- Bellow seals

- Cartridge seals

- Labyrinth seals

- Radial shaft seals

- Axial shaft seals

- Reduces leakage: It can significantly reduce gas or steam leakage, thus improving the overall performance and efficiency of the turbine.

- Prevent contamination: A high-quality shaft sealing system can also prevent contaminants such as dust, dirt, and water from entering the turbine, which can reduce the risk of corrosion and other types of parts damage.

- Improve reliability: It can reduce the risk of unplanned downtime and maintenance, which can improve the overall reliability of the turbine.

- Enhance safety: A properly functioning seal can also help to prevent potentially hazardous leaks or releases of steam or gas, which can improve the safety of the turbine and its operators.