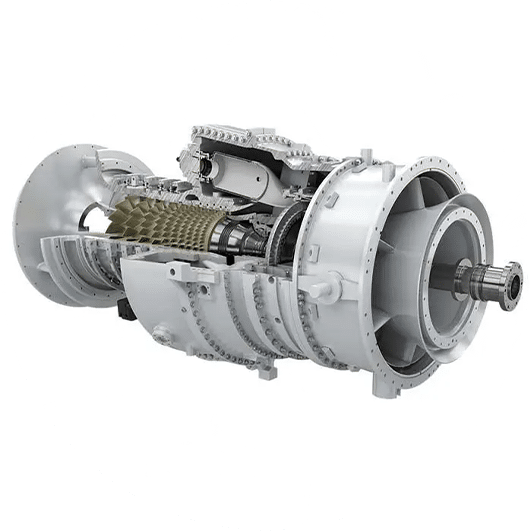

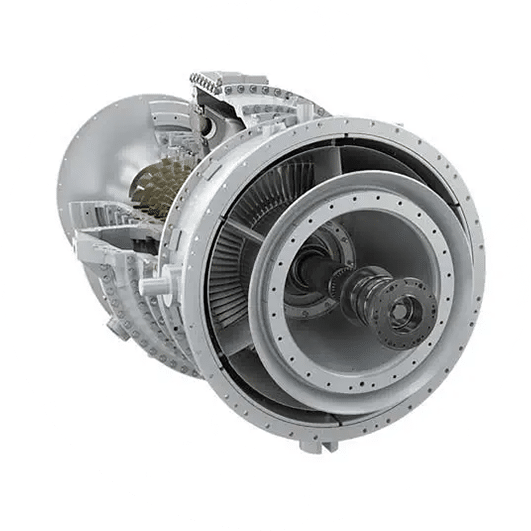

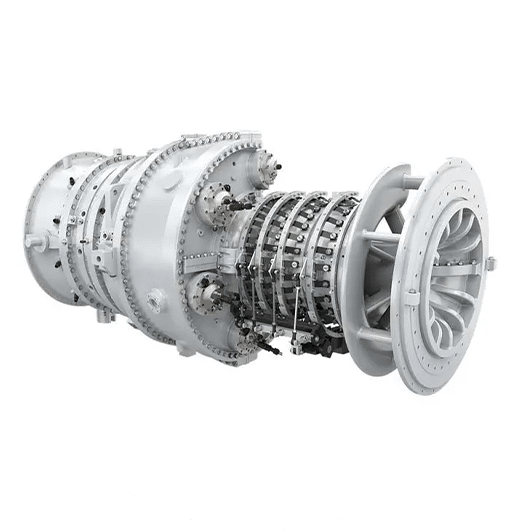

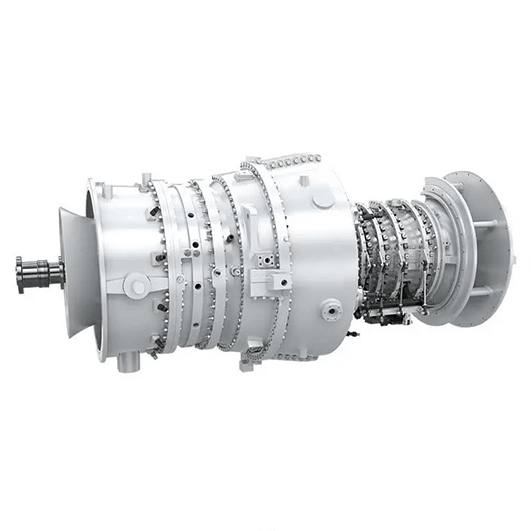

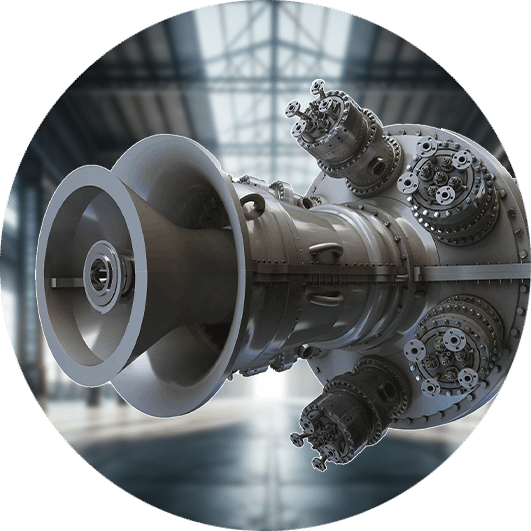

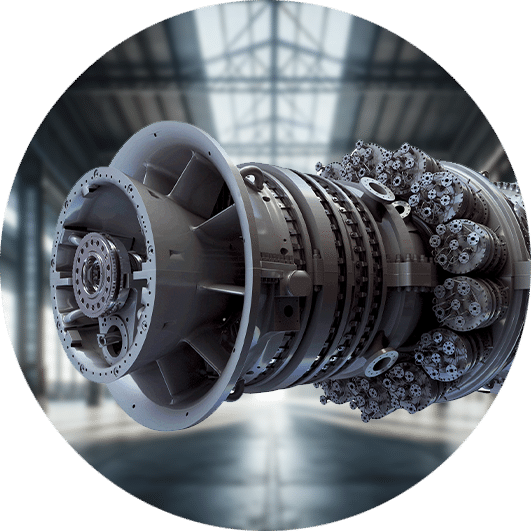

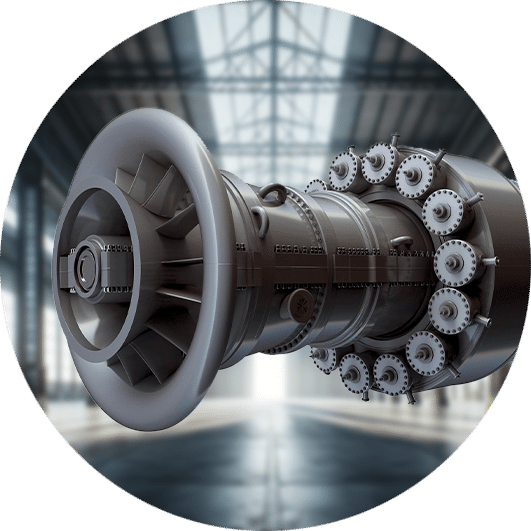

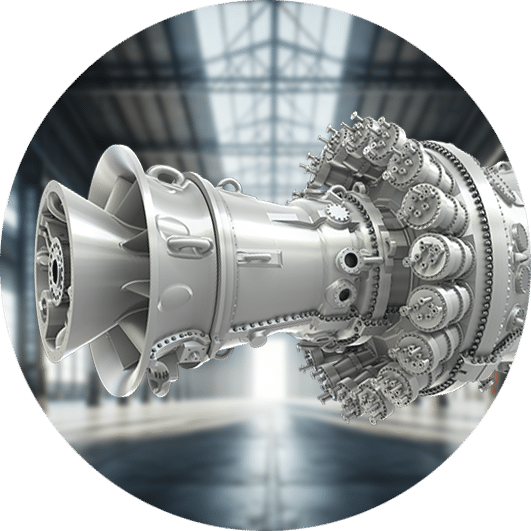

Siemens 101 Gas Turbine Repair Services

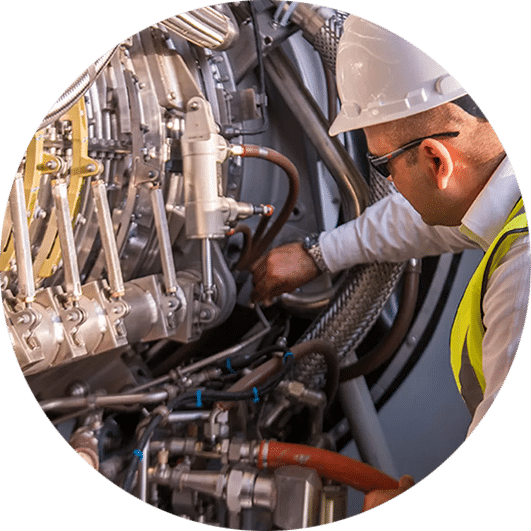

Expert Repairs for Siemens 101 Units — Legacy Performance, Modern Solutions

At Allied Power Group, we provide full-scope repair and restoration services for Siemens 101 gas turbines. These legacy units are still vital to many industrial and utility operations—but maintaining their performance requires experienced hands, fast turnaround, and OEM-alternative solutions. Whether you need a rotor rebuild, combustion system upgrade, or critical part replacement, our integrated engineering, field, and shop teams deliver the speed, quality, and precision your operation demands—without the extended lead times or costs of OEM support.300+

Siemens Blades Repaired

400+

Siemens Vanes Repaired

580+

Siemens Ring Segments Repaired

290+

Siemens Nozzles Repaired