Mitsubishi 701F Gas Turbine Repair Services

High-Performance Repairs for Mitsubishi 701F Units — Fast, Engineered, and Built for Results

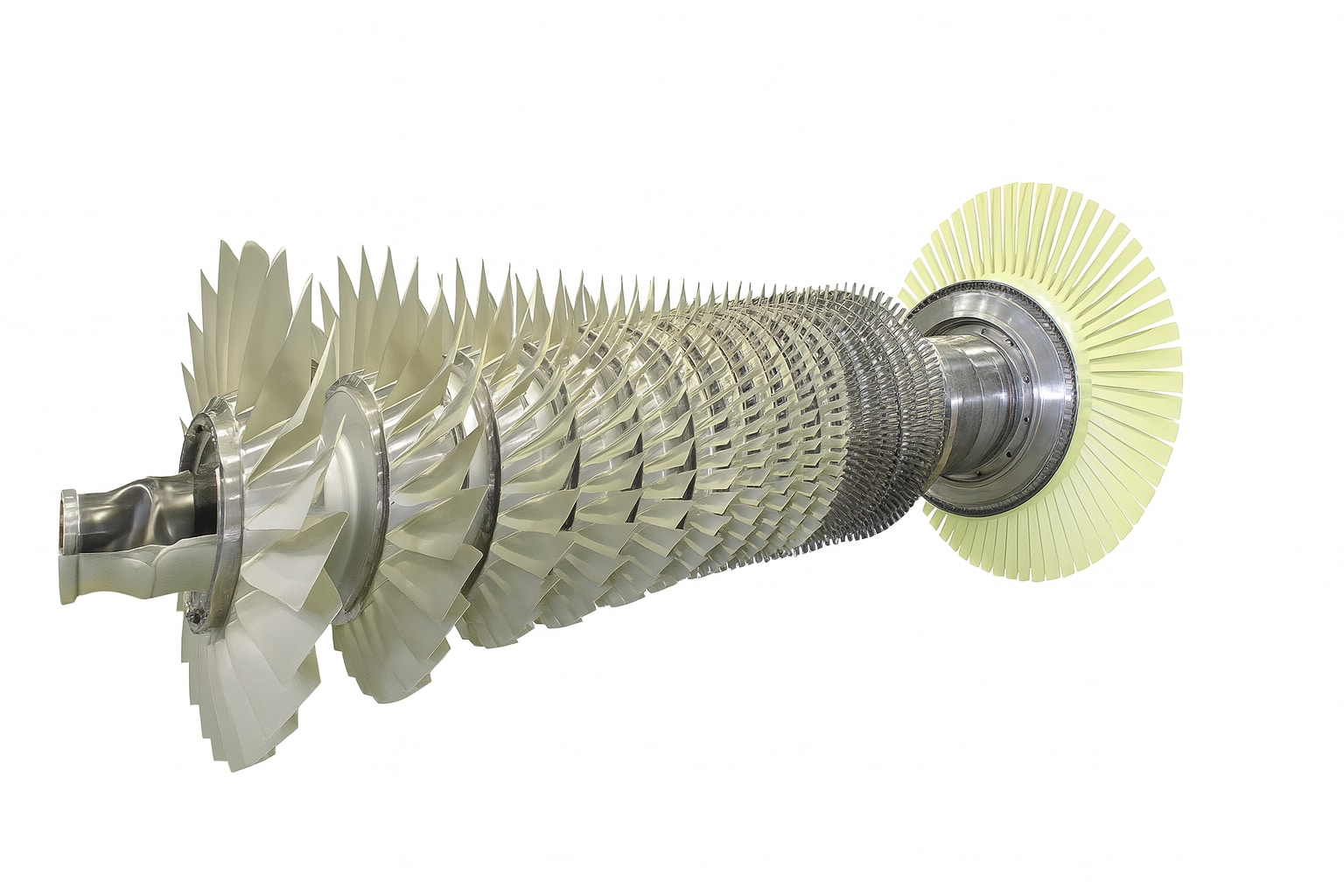

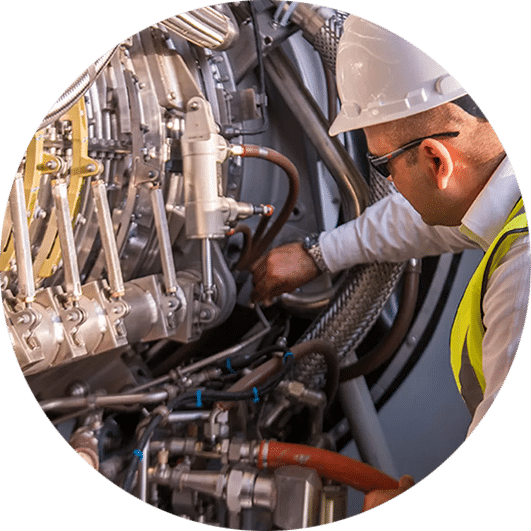

Allied Power Group delivers expert repair, field service, and engineering solutions for Mitsubishi 701F gas turbines. As one of Mitsubishi’s most advanced and high-output machines, the 701F is a critical asset in combined-cycle and baseload operations. With our integrated repair facility, on-site field teams, and in-house engineers, we restore Mitsubishi 701F turbines to peak performance while reducing lead times and total cost of ownership. Whether you're managing a planned outage, addressing combustion issues, or replacing hot gas path components, we provide a complete, OEM-alternative solution tailored to your operational goals.