Power generation facilities face significant challenges in maintaining equipment integrity. Undetected structural flaws in rotating machinery can progress from minor surface defects to catastrophic failures. This guide focuses on the critical methods for detecting cracks in gas turbine blades.

Allied Power Group, based in Houston, Texas, offers decades of experience in industrial gas turbine repair. Our expertise is invaluable in guiding the implementation of effective crack detection protocols. Maintenance professionals and plant operators depend on these proven methods to maintain operational continuity.

Industry data shows the high cost of equipment failures. Minor repairs can cost tens of thousands of dollars if caught early. On the other hand, catastrophic turbine blade failures can lead to millions in damages and extended downtime. Early detection through systematic crack detection can turn these disasters into manageable maintenance tasks.

Key Takeaways

- Early crack detection prevents minor defects from becoming catastrophic failures

- Proactive maintenance strategies reduce repair costs from millions to thousands of dollars

- Multiple inspection methodologies ensure a thorough structural integrity assessment

- Regular monitoring protocols maintain operational safety and efficiency standards

- Professional expertise is essential for implementing effective detection programs

- Industry best practices combine traditional and advanced testing techniques

Introduction to Crack Detection in Turbine Blades

Modern power generation systems rely heavily on the integrity of turbine blades for safe and efficient operation. These critical components face extreme thermal and mechanical stresses, making crack detection vital to prevent catastrophic failures. Allied Power Group’s extensive experience in industrial gas turbine repair highlights the importance of understanding blade operational environments for effective maintenance strategies.

The complexity of turbine systems demands specialized knowledge of how different blade configurations respond to operational stresses. Whether in gas turbine engines or steam turbines, crack detection methodologies must consider unique operational characteristics. This approach ensures both immediate safety and long-term operational reliability.

The Role of Turbine Blades in Power Generation

Turbine blades are the primary energy conversion components in power generation systems. They transform fluid energy into mechanical work through carefully engineered aerodynamic profiles. In gas turbine engines, blades extract energy from high-temperature combustion gases to drive the rotor assembly.

Steam turbine applications use similar principles but operate with different fluid properties and temperature ranges. Blade design varies significantly between axial and centrifugal configurations. Axial turbines have blades parallel to the rotor axis, while centrifugal designs have blades radially outward.

Compressor blades face unique challenges as they compress incoming air or gas. These components experience different stress patterns compared to turbine blades. The operational environment directly influences crack initiation and propagation characteristics.

| Turbine Type | Operating Temperature | Primary Stress Factors | Common Crack Locations |

|---|---|---|---|

| Gas Turbine Engine | 1000-1600°C | Thermal cycling, centrifugal force | Leading edge, root attachment |

| Steam Turbine | 400-650°C | Moisture erosion, vibration | Trailing edge, blade tip |

| Compressor | 200-500°C | Foreign object damage, fatigue | Leading edge, mid-span |

| Industrial Turbine | 800-1200°C | Corrosion, thermal stress | Root fillet, platform area |

Why Crack Detection is Critical for Safety and Efficiency

Undetected cracks in turbine blades can lead to catastrophic failures with severe consequences. Single blade failures have resulted in complete turbine collapse in documented cases across the wind industry. The high rotational speeds and extreme operating conditions amplify the impact of even small defects.

Forced response conditions create dangerous scenarios for crack propagation. These occur when blade natural frequencies align with excitation frequencies from the turbine engine operation. The resulting vibrations accelerate crack growth and can cause rapid failure progression.

Economic implications extend beyond immediate repair costs. Unplanned outages disrupt power generation schedules and create significant revenue losses. Early crack detection enables planned maintenance windows that minimize operational disruptions.

Safety considerations encompass both personnel protection and environmental impact. Blade failures can generate high-energy debris that poses risks to nearby equipment and personnel. Proper crack detection protocols help maintain safe operating environments.

Scope and Objectives of This Guide

This guide addresses crack detection methodologies across various turbine applications. Coverage includes industrial gas turbines, steam turbines, and compressor systems. The content applies to both axial and centrifugal turbine configurations.

Primary objectives focus on establishing effective inspection protocols that ensure operational safety. The guide provides practical implementation strategies based on real-world experience. Allied Power Group’s Houston-based operations contribute valuable insights from diverse industrial applications.

Technical depth progresses from fundamental concepts to advanced detection methods. Readers gain understanding of inspection planning, execution, and result interpretation. The content prepares maintenance professionals for implementing complete crack detection programs.

Regulatory compliance requirements receive detailed attention throughout the guide. Industry standards and best practices form the foundation for recommended procedures. The scope encompasses both immediate safety concerns and long-term reliability optimization strategies.

Understanding Turbine Blade Cracks

Grasping the essence of turbine blade cracks is key to effective inspection strategies. Turbine blades face extreme conditions, leading to stress pathways that initiate and grow cracks. Research indicates that crack formation is influenced by operating conditions, material properties, and design factors.

Allied Power Group’s extensive repair experience in Houston’s industrial gas turbine sector shows that most blade failures stem from identifiable crack mechanisms. These mechanisms develop over time due to repeated exposure to operational stresses. Understanding these patterns allows maintenance teams to predict failure timelines and plan effective interventions.

Common Causes of Cracks

Fatigue crack initiation is the most prevalent failure mechanism in turbine blades. These cracks start at stress concentration points, where geometric features amplify stress. Manufacturing defects, surface irregularities, and design transitions are common initiation sites.

Thermal stress significantly contributes to crack development in gas turbines. Rapid temperature changes during startup and shutdown cycles cause differential expansion and contraction. This thermal cycling generates stress patterns that exceed material fatigue limits over time.

Mechanical loading from centrifugal forces and aerodynamic pressures creates additional stress pathways. High-frequency vibrations and resonance conditions can accelerate crack initiation at vulnerable locations. Corrosion and oxidation further weaken blade surfaces, creating additional crack nucleation sites.

Types of Cracks

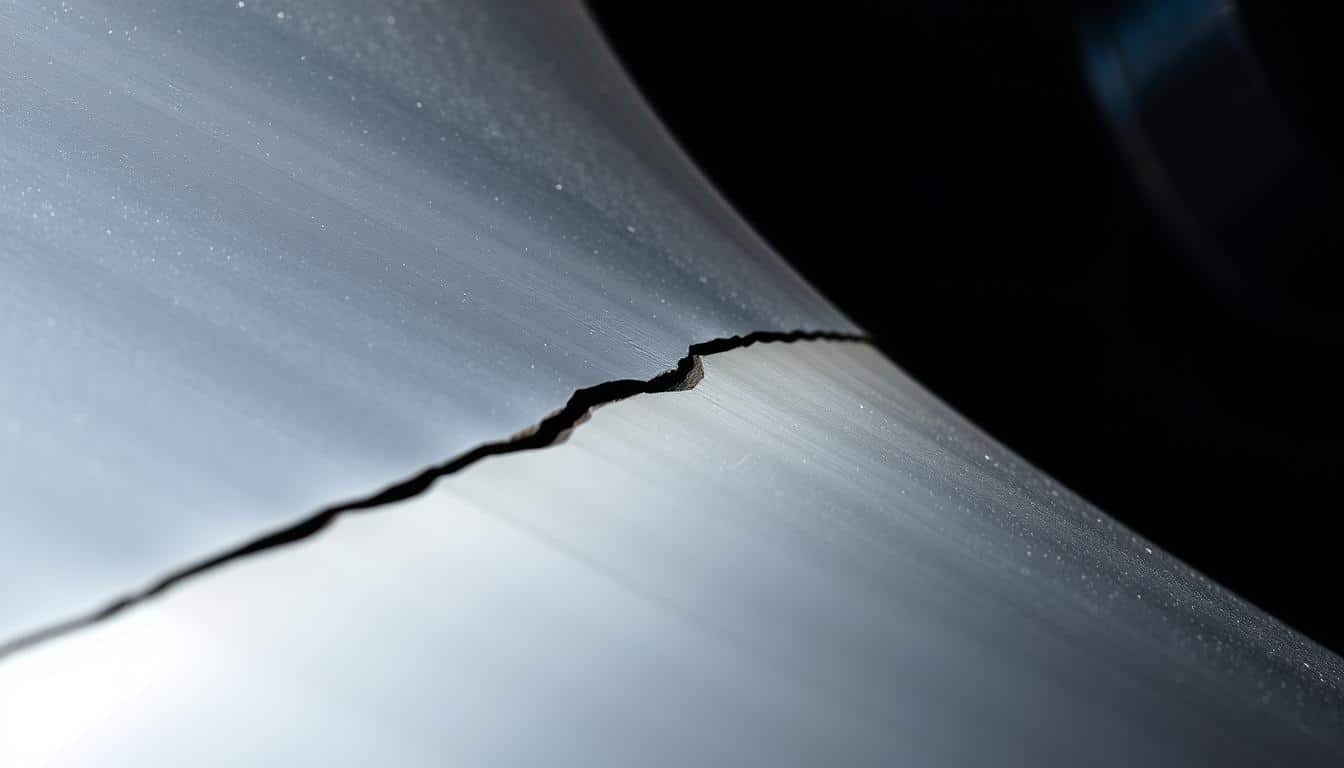

Surface cracks are the most detectable form of blade damage during routine inspections. These cracks originate at the blade surface and remain visible through conventional examination methods. Surface-breaking discontinuities provide immediate detection opportunities but indicate advanced damage states requiring prompt attention.

Internal cracks develop within the blade material without reaching the surface initially. These hidden defects require advanced non-destructive testing techniques for identification. Internal cracks pose significant risks because they remain undetected until propagation reaches critical dimensions.

| Crack Type | Detection Method | Risk Level | Typical Location |

|---|---|---|---|

| Surface Cracks | Visual Inspection | Medium | Leading/Trailing Edges |

| Internal Cracks | Ultrasonic Testing | High | Blade Root/Airfoil |

| Thermal Fatigue | Dye Penetrant | High | Hot Gas Path |

| Stress Corrosion | Eddy Current | Medium | Cooling Passages |

Crack Growth and Propagation Patterns

Crack propagation follows predictable patterns determined by stress distribution and material properties. Fatigue cracks typically grow perpendicular to principal stress directions, creating characteristic crack paths. Understanding these patterns helps inspectors focus on high-probability locations during examinations.

Thermal fatigue creates unique propagation characteristics influenced by temperature gradients and material expansion coefficients. These cracks often exhibit branching patterns as they encounter varying stress fields within the blade structure. Growth rates accelerate under combined thermal and mechanical loading conditions.

Environmental factors significantly influence crack propagation behavior. Corrosive atmospheres accelerate growth rates through stress corrosion mechanisms. High-temperature exposure affects material properties, altering crack growth resistance and changing propagation patterns from those observed in laboratory conditions.

Crack growth monitoring reveals that small discontinuity defects can remain stable for extended periods under normal operating conditions. Changes in operating parameters or unexpected transient events can trigger rapid propagation phases. This behavior emphasizes the importance of regular inspection intervals and a thorough crack detection program.

Risks and Consequences of Undetected Cracks

Crack detection failures lead to significant risks for facilities, affecting both safety and profitability. The missed identification of cracks can lead to repair costs that skyrocket from $10,000 to over $1,000,000. Wind industry studies show that 70% of severe damage is due to cracks.

Allied Power Group’s expertise in industrial gas turbine repair highlights the cost escalation from delayed crack detection. Effective health monitoring systems are essential to prevent these consequences.

Operational Efficiency Loss

Small cracks can subtly affect turbine blade performance, leading to reduced efficiency. These defects alter aerodynamics and cause vibrations, decreasing power output.

Facilities see increased fuel consumption as turbines work harder to meet output targets. This can result in monthly revenue losses of thousands of dollars before issues are identified.

Advanced diagnostics systems detect surface irregularities, preventing efficiency losses. Regular health monitoring catches performance degradation early, avoiding significant cost impacts.

Risk of Catastrophic Failure

Undetected cracks can lead to blade separation during operation, posing severe safety risks. This scenario can cause immediate hazards to personnel and infrastructure.

High-velocity blade fragments can damage adjacent components, leading to costly turbine rebuilds. Emergency shutdowns due to catastrophic failures result in extended outages and high repair costs.

Regular inspection programs prevent crack progression to failure-critical stages. Early intervention transforms disasters into scheduled maintenance.

Maintenance and Repair Cost Escalation

Delayed crack detection leads to exponentially higher costs. Surface cracks detected early require minor repairs costing thousands.

Advanced repairs for structural damage, including major component replacement or blade refurbishment, can exceed $100,000 per blade. These repairs require specialized facilities and extended lead times.

Allied Power Group’s Houston operations show a cost ratio of over 100:1 between early detection repairs and catastrophic failure responses. Early detection avoids the high costs of advanced damage repairs.

Impact on Plant Downtime and Production

Unplanned outages due to blade failures disrupt operations beyond immediate repair times. Emergency shutdowns can affect contractual power delivery and grid stability.

Extended downtime for catastrophic failure repairs can last weeks or months, depending on availability and complexity. These outages strain customer relationships and threaten revenue contracts.

Scheduled maintenance windows enabled by early detection minimize downtime impacts. Facilities maintain availability while addressing issues before they become failures.

Comprehensive crack detection programs offer significant returns on investment. They prevent failures, reduce maintenance costs, and ensure operational reliability, supporting profitability and safety.

Industry Standards and Regulatory Requirements

Industry standards are the backbone for reliable crack detection in turbine operations. They provide a framework that ensures inspections meet safety standards while keeping operations efficient. This compliance safeguards both personnel and equipment investments across various turbine applications.

Professional crack detection programs face a complex regulatory landscape. Standards differ greatly among turbine types and operational settings. Grasping these requirements is essential for maintaining proper licensing and insurance.

ASME and ISO Standards

The ASME Digital Collection offers detailed guidelines for nondestructive testing in turbine blade evaluation. These standards set minimums for personnel qualifications and equipment calibration. Adherence to these benchmarks ensures inspection programs are reliable.

ISO standards add an international layer to ASME requirements, focusing on quality management. These are critical for facilities operating globally. They cover documentation and testing procedures for consistent results.

Key ASME and ISO requirements include:

- Personnel certification and training standards

- Equipment calibration and maintenance protocols

- Documentation and traceability procedures

- Quality assurance program requirements

OEM Guidelines

OEM guidelines often surpass general industry standards. They reflect proprietary knowledge of material properties and stress patterns. OEMs address specific failure modes unique to their turbine designs.

Manufacturers outline detailed procedures for NDT methods specific to their equipment. These guidelines specify inspection intervals and acceptance criteria. Adhering to OEM recommendations ensures warranty coverage and operational reliability.

OEM compliance typically requires:

- Manufacturer-approved inspection techniques

- Specific equipment and material specifications

- Detailed reporting and documentation formats

- Regular updates to reflect design improvements

Aviation vs. Industrial Turbine Compliance Requirements

Aviation and industrial turbine standards have distinct requirements. Aviation demands more frequent inspections due to its safety-critical nature. These standards have lower thresholds for flaw acceptance.

Industrial turbine compliance focuses on operational efficiency while maintaining safety. It allows for more flexible inspection scheduling based on operational demands. Risk assessment approaches vary between these two sectors.

Allied Power Group’s compliance expertise ensures adherence to industry standards while implementing practical crack detection solutions. Their experience in Houston’s industrial gas turbine sector showcases effective regulatory navigation. This approach balances compliance with operational flexibility for power generation facilities.

Pre-Inspection Preparations

Effective turbine blade crack detection hinges on thorough preparation. This includes ensuring safety, surface conditions, and meeting documentation standards. The quality of this groundwork directly affects the accuracy of inspections and the safety of personnel. Allied Power Group’s field experience shows that poor preparation can lead to missed defects and unreliable inspections.

Establishing proper preparation protocols is key to successful non-destructive testing. Each step must adhere to regulatory standards while preserving the integrity of the components. The quality of preparation determines whether cracks are detected or remain hidden under contaminants.

Safety Protocols for Inspection Teams

Ensuring the safety of inspection teams is critical. They must follow strict protocols to handle the hazards of the turbine environment. Lockout/tagout procedures are essential before starting any inspection work. The risk of burns from residual heat requires proper cooling periods and temperature checks.

When inspecting internal blade passages or turbine casings, confined space entry procedures apply. Teams need to monitor the atmosphere for oxygen deficiency or toxic gases. Personal protective equipment, including heat-resistant gloves, safety glasses, and respiratory gear, is necessary when using cleaning chemicals.

Exposure to hazardous materials is a risk during coating removal and cleaning. Many thermal barrier coatings contain materials that require special handling. Teams must be familiar with the safety data sheets for all chemicals used in surface preparation.

Blade Cleaning and Surface Preparation

Surface preparation is vital for crack detection across all inspection methods. Deposits, corrosion products, and protective coatings can hide cracks from view. The cleaning process must remove these contaminants without damaging the blade material.

Removing coatings poses unique challenges. It requires balancing inspection needs with component protection. Experimental studies have shown that improper removal can introduce damage that looks like cracks.

Chemical cleaning methods vary based on the type of deposit and the material of the blade. Alkaline cleaners remove combustion deposits, while acid solutions target corrosion. Ultrasonic cleaning effectively removes contaminants from complex geometries without causing mechanical damage.

Thermographic and infrared thermography require specific surface preparation. The surface emissivity must be consistent across inspection areas for accurate thermal measurements. Experimental studies indicate that surface finish variations can create false thermal signatures, interfering with crack detection.

| Preparation Method | Application | Advantages | Limitations |

|---|---|---|---|

| Chemical Cleaning | Deposit Removal | Thorough cleaning, no mechanical damage | Chemical handling requirements |

| Abrasive Blasting | Coating Removal | Fast removal, uniform surface | Potential substrate damage |

| Ultrasonic Cleaning | Complex Geometries | Reaches all surfaces, gentle process | Limited to smaller components |

| Laser Cleaning | Selective Removal | Precise control, minimal waste | High equipment cost |

Documentation and Traceability Requirements

Comprehensive documentation is essential for regulatory compliance and quality assurance. It captures all preparation procedures, environmental conditions, and personnel qualifications involved in the inspection. This documentation supports the validity of inspections and provides traceability for future reference.

Documentation of preparation procedures includes cleaning methods, chemicals used, and surface conditions before and after treatment. Digital photography provides visual records of surface conditions at each stage. These images are critical for evaluating inspection results and planning future maintenance activities.

Personnel qualification records verify that inspection teams have the required certifications and training. Documentation must include NDT certification levels, safety training completion, and equipment operation qualifications. Finite element method analysis often supports preparation procedure development and requires proper documentation of modeling assumptions and results.

Monitoring environmental conditions during preparation ensures optimal inspection conditions. Temperature, humidity, and lighting levels affect both preparation effectiveness and subsequent inspection accuracy. Automated data logging systems provide continuous monitoring with timestamped records that support inspection validity.

Visual Inspection Techniques

Visual inspection is key in detecting turbine blade cracks, giving immediate insights into surface defects. These methods are the most straightforward way to spot cracks, erosion, and coating wear that hint at deeper structural issues. Allied Power Group employs advanced visual inspection tools to enhance traditional methods in gas turbine applications.

The success of visual inspection hinges on several factors. The skill of the inspector, the quality of lighting, and access to areas all play a role. Modern image processing technologies boost traditional methods by providing digital records and automated defect spotting.

Direct Visual Examination

Direct visual examination is the most basic yet effective technique for assessing turbine blades. It allows inspectors to spot surface cracks, erosion, and material wear through direct observation. This method excels in finding damage on blade edges and tips, where stress is highest.

Proper lighting is essential for success in direct examination. High-intensity LED lights ensure consistent illumination, revealing even the smallest surface irregularities. Magnification tools, like handheld magnifiers and digital microscopes, help spot micro-cracks that might be missed by the naked eye.

Clean blade surfaces are critical for quality examination. Blades free from deposits and coatings allow for better crack detection. Inspectors must systematically check all surfaces, following established patterns to ensure thoroughness.

Remote Visual Inspection (Borescope)

Remote visual inspection with borescope technology extends the reach to internal blade areas and hard-to-reach spots. It’s vital for inspecting turbine vanes and composite blades where internal damage may not show on the outside. Modern borescopes have high-resolution cameras and flexible tubes that can navigate complex internal spaces.

Advanced borescope systems use image processing to enhance defect visibility. They can document findings with precise measurements and create permanent records for analysis. Thermography integration with borescope inspection reveals thermal signatures from crack-induced heat transfer changes.

This technology allows for the inspection of cooling passages, internal vane structures, and areas that require component removal for examination. High-frequency vibration analysis during borescope inspection can identify dynamic responses indicating structural changes in composite materials where visual signs are subtle.

Limitations of Visual Methods

Visual inspection methods have inherent limitations that need to be understood for effective use. They cannot detect subsurface defects that may exist below the visible surface layer. Crack detection heavily relies on surface preparation quality and lighting conditions, which can vary.

Inspector subjectivity is another significant limitation. Different inspectors may interpret the same indication differently, leading to inconsistent results. This variability requires standardized training and qualification procedures to ensure reliability.

Resonance and resonant frequency analysis can complement visual methods by identifying structural changes not apparent through optical examination. Yet, visual techniques alone cannot provide quantitative crack depth measurements or assess crack growth rates accurately. These limitations necessitate integration with non-destructive testing methods for a complete evaluation.

| Inspection Method | Detection Capability | Access Requirements | Documentation Level | Cost Factor |

|---|---|---|---|---|

| Direct Visual | Surface cracks >0.5mm | Direct line of sight | Basic photography | Low |

| Borescope Standard | Surface cracks >0.3mm | Small access ports | Digital imaging | Medium |

| Advanced Borescope | Surface cracks >0.1mm | Minimal access required | High-resolution recording | High |

| Thermography Enhanced | Thermal anomalies | External access only | Thermal mapping | Medium-High |

Combining multiple visual inspection techniques provides a thorough examination of turbine blade surfaces. Direct examination covers accessible external areas, while borescope technology addresses internal and restricted access zones. Understanding these limitations guides the selection of complementary inspection methods for complete crack detection programs.

Visual inspection effectiveness varies by blade location. Outboard sections show higher damage detection rates compared to internal structural areas. This variation influences inspection planning and resource allocation for optimal detection coverage across all critical blade regions.

Non-Destructive Testing (NDT) Methods for Crack Detection

Non-destructive testing methods are key to accurate crack detection in turbine blade inspection. These advanced techniques allow for thorough evaluation of blade integrity without damaging critical components. Allied Power Group uses a range of NDT methods to ensure reliable crack detection across various materials and configurations.

Different NDT methods vary in effectiveness, each with unique advantages for specific scenarios. The choice of method depends on material properties, crack location, and accessibility. Professional teams combine multiple NDT approaches for maximum detection reliability.

Dye Penetrant Inspection (DPI)

Dye penetrant inspection is a cost-effective method for detecting surface-breaking cracks. It relies on capillary action principles. This technique is valuable for initial screening of blade surfaces where visual inspection is insufficient.

The effectiveness of DPI depends on proper surface preparation and adequate dwell time. Under optimal conditions, it can detect cracks as small as 0.1mm in width. Surface contaminants and improper cleaning can significantly reduce detection sensitivity.

DPI works effectively on both metallic and non-metallic materials. It requires accessible surfaces and cannot detect subsurface defects. Processing time varies from 30 minutes to several hours, depending on penetrant type and environmental conditions.

Magnetic Particle Inspection (MPI)

Magnetic particle inspection offers superior sensitivity for ferromagnetic materials commonly found in turbine blade construction. This technique uses magnetic field distortions to reveal both surface and slightly subsurface defects. MPI can detect discontinuities that other methods might miss.

The method requires magnetization of the test component using either direct current or alternating current. Magnetic particles applied to the surface concentrate at areas of flux leakage caused by cracks. Fluorescent particles under ultraviolet light enhance defect visibility.

MPI limitations include applicability only to ferromagnetic materials and the need for demagnetization after testing. The technique excels at detecting fatigue cracks in high-stress blade areas where geometric constraints limit other inspection methods.

Eddy Current Testing (ECT)

Eddy current testing is one of the most versatile NDT approaches for turbine blade inspection. This method generates electromagnetic fields that induce eddy currents in conductive materials. Changes in current flow patterns indicate the presence of cracks or other discontinuities.

Eddy current array configurations enable rapid scanning of large blade surfaces while maintaining high sensitivity to surface and near-surface cracks. Using eddy current methods on conductive materials provides real-time crack detection capabilities. The technique offers immediate results without requiring post-processing time.

Specialized probe designs adapt to complex blade geometries and cooling passage inspections. Allied Power Group’s experience demonstrates how using eddy current testing enables detection of cracks in previously inaccessible areas. The method works effectively on blades using various alloy compositions.

Eddy-current techniques prove effective for detecting fatigue cracks in high-stress areas. The method can differentiate between surface and subsurface defects based on signal characteristics. Probe frequency selection affects penetration depth and resolution capabilities.

| NDT Method | Detection Depth | Material Types | Crack Size Sensitivity | Real-time Results |

|---|---|---|---|---|

| Dye Penetrant | Surface only | All materials | 0.1mm width | No |

| Magnetic Particle | Near-surface | Ferromagnetic only | 0.05mm width | Yes |

| Eddy Current | 0-6mm depth | Conductive materials | 0.1mm length | Yes |

| Ultrasonic | Full thickness | All solid materials | 0.5mm diameter | Yes |

Ultrasonic Testing (UT)

Ultrasonic testing provides the deepest penetration capabilities among NDT methods used for turbine blade inspection. This technique uses high-frequency sound waves to detect internal defects and measure crack dimensions. UT enables detection of subsurface discontinuities that other methods cannot reach.

The method supports critical repair versus replacement decisions through accurate crack sizing capabilities. Ultrasonic waves reflect from crack surfaces, providing information about defect location, size, and orientation. Advanced techniques include phased array and time-of-flight diffraction methods.

UT requires skilled operators and proper calibration standards for reliable results. The technique works effectively on thick sections and complex geometries. Coupling medium ensures proper sound transmission between the probe and test surface.

Blades using different materials and construction methods require tailored ultrasonic approaches. Frequency selection affects penetration depth and resolution. Higher frequencies provide better resolution but limited penetration, while lower frequencies penetrate deeper with reduced sensitivity.

On-Site vs. Off-Site Inspection

Modern turbine maintenance strategies must balance the immediacy of on-site inspections with the detailed capabilities of controlled shop environments. This critical decision impacts detection accuracy, operational costs, and maintenance scheduling. Understanding the strengths and limitations of each approach is key to optimizing inspection strategies.

The choice between field and shop-based inspections hinges on several factors. These include operational urgency, detection requirements, and available resources. Each setting offers distinct advantages that serve different maintenance objectives.

Field Inspection Capabilities

Field inspections provide immediate assessment capabilities without requiring component removal. This approach enables rapid evaluation during scheduled maintenance windows or emergency situations. Maintenance teams can quickly identify surface defects and make immediate operational decisions.

On-site inspections excel at detecting visible cracks on turbine components and surface anomalies. Portable NDT equipment allows technicians to perform basic evaluations while components remain installed. This approach minimizes downtime and reduces handling risks associated with component removal.

Field conditions, though, present significant limitations. Environmental factors such as temperature, humidity, and lighting can compromise inspection quality. Access restrictions often prevent thorough examination of all blade surfaces, making steam turbine blade assemblies challenging.

Detecting internal defects becomes challenging in field environments. Equipment constraints and space limitations reduce the effectiveness of advanced NDT methods. These factors may result in missed defects that could lead to future failures.

Shop-Based Inspection Advantages

Shop-based inspections offer controlled environmental conditions that enhance detection capabilities. Dedicated facilities provide optimal lighting, temperature control, and vibration-free environments. These conditions enable precise measurements and detailed analysis.

Allied Power Group’s Houston-based facilities demonstrate the capabilities of shop inspection. Their controlled environment allows systematic evaluation of blade vibration characteristics and excitation response patterns. Advanced equipment enables detailed crack mapping that supports thorough repair planning.

Shop environments excel at detecting internal defects that field inspections might miss. Multiple NDT methods can be applied simultaneously, providing a complete evaluation of compressor blade and steam turbine blade conditions. This thorough approach identifies subtle defects before they become critical.

The controlled setting enables precise documentation and measurement. Technicians can perform detailed analysis of turbine blades using specialized equipment unavailable in field conditions. This approach supports accurate repair versus replacement decisions.

Choosing the Right Setting

Selecting the appropriate inspection environment requires careful consideration of multiple factors. Operational constraints, detection requirements, and cost considerations all influence this decision. Emergency situations may favor field inspections despite their limitations.

Planned maintenance activities often benefit from shop-based evaluations. The detailed detection capabilities justify the additional time and cost when thorough assessment is required. This approach proves valuable for critical components with high failure consequences.

| Inspection Factor | Field Inspection | Shop-Based Inspection | Optimal Application |

|---|---|---|---|

| Detection Capability | Surface defects only | Internal and surface defects | Shop for complete analysis |

| Downtime Impact | Minimal | Extended | Field for emergency situations |

| Equipment Access | Portable tools only | Full NDT laboratory | Shop for advanced testing |

| Environmental Control | Variable conditions | Controlled environment | Shop for precision work |

| Cost Efficiency | Lower immediate cost | Higher upfront investment | Depends on failure risk |

Decision-making frameworks help maintenance professionals balance immediate availability benefits against detailed detection capabilities. Emergency situations requiring immediate operational decisions may necessitate field inspections despite their limitations.

Planned maintenance programs should prioritize shop-based evaluations when detailed assessment is critical. This approach ensures that subtle internal defects are detected before they compromise operational safety or efficiency.

The optimal strategy often combines both approaches. Initial field screening can identify obvious defects requiring immediate attention. Subsequent shop-based evaluation provides a detailed analysis for long-term maintenance planning.

Resource utilization and maintenance effectiveness improve when inspection strategies align with operational requirements and safety objectives. This balanced approach ensures that detection capabilities match the criticality of the components being evaluated.

Repair vs. Replacement Decisions

After diagnosing cracks in turbine blades, teams must decide between repair or replacement. This choice affects maintenance costs, downtime, and future reliability. It requires evaluating technical and economic factors carefully.

Early detection allows for repair in about 70% of cases. Yet, advanced cracks often require blade replacement. Accurate damage assessment and repair feasibility evaluation are key.

Allied Power Group in Houston offers cost-effective repairs for cracked turbine blades. Their skilled technicians provide honest advice on when replacement is needed. This ensures efficient use of resources and long-term success.

Assessment Standards for Repair Viability

Repair viability depends on several factors, including crack size. Specific limits vary by turbine type. Surface cracks under 0.5 inches are often repairable, while deeper ones need more evaluation.

Crack location is also critical. Non-critical areas can be repaired, but defects near roots or edges may not be. Precise location data from detection methods is essential for these assessments.

Crack orientation impacts risk. Longitudinal cracks are generally safer than transverse ones. Health monitoring systems track crack behavior, aiding in repair planning.

| Crack Characteristic | Repair Feasible | Marginal Case | Replacement Required |

|---|---|---|---|

| Surface Length | Under 0.5 inches | 0.5 to 1.0 inches | Over 1.0 inches |

| Depth Penetration | Less than 10% thickness | 10% to 25% thickness | Over 25% thickness |

| Location Impact | Non-critical zones | Secondary stress areas | Primary load paths |

| Propagation Rate | Stable or slow | Moderate growth | Rapid expansion |

Proven Restoration Techniques

Several methods effectively address turbine blade cracks when repair is possible. Crack stop drilling is the most common, drilling holes to halt crack growth. This method redistributes stress and prevents further propagation.

Welding is effective for certain cracks and locations. Technicians remove damaged material and rebuild the area using compatible welding. Heat treatment is critical to maintain metallurgy and prevent stress issues.

Composite patching is an alternative for surface defects. High-strength composites bond to the blade, reinforcing the damaged area. This method is ideal for gas turbines where weight is a concern.

Material replacement involves removing the cracked section and installing new material. This method ensures defect removal but requires extensive work. It’s most effective for large defects beyond other repair capabilities.

Circumstances Requiring Complete Replacement

Some cracks necessitate replacement for safety. Exceeding established size limits is a primary trigger. Repair attempts may compromise safety margins beyond acceptable limits.

Cracks in critical areas, like roots or attachment points, require replacement. These areas face maximum stresses, making repaired sections unreliable. Replacement ensures restored reliability.

Inaccessible locations prevent effective repair. Some defects are in areas unreachable by repair tools or where quality control is impossible. Replacement ensures complete defect elimination and reliability.

Multiple crack systems indicate widespread material degradation. When numerous defects are found in a single blade, replacement is more cost-effective. This approach eliminates the risk of additional crack development.

Economic factors sometimes favor replacement over complex repairs. When repair costs approach replacement costs, new blades offer better long-term value. They provide extended service life and eliminate repair concerns.

Summary

Effective gas turbine blade crack detection is a vital investment in both safety and economic performance. This guide outlines how systematic crack detection programs significantly reduce failure costs. They also enhance reliability across all turbine applications.

Modern turbine blade crack detection involves combining various inspection techniques. Visual examination offers an initial assessment. Advanced methods like eddy current testing and ultrasonic inspection pinpoint subsurface defects accurately. This multi-layered approach ensures thorough coverage of different failure modes.

Allied Power Group’s experience in Houston’s industrial sector highlights the benefits of proactive blade crack detection. Facilities with structured inspection protocols see longer component lifespans and better maintenance scheduling. These programs are key to asset management, balancing safety with economic needs.

The shift from reactive to predictive maintenance in gas turbine blade crack detection yields significant gains. Investing in training, equipment upkeep, and procedure development avoids major failures and cuts downtime. Successful implementation hinges on understanding facility needs while staying adaptable to industry advancements.

FAQ

What are the most common types of cracks found in gas turbine blades?

Common types include fatigue cracks at stress points and thermal fatigue from temperature changes. Surface-breaking cracks are visible, while internal ones need advanced tests. Surface cracks show advanced damage, and internal ones may go unnoticed until they grow large.

Which non-destructive testing methods are most effective for turbine blade crack detection?

Eddy current testing is versatile for conductive materials and detects cracks in real-time. Ultrasonic testing finds internal defects and sizes cracks. DPI is cost-effective for surface cracks, and MPI is best for ferromagnetic materials. Eddy current arrays quickly scan large surfaces with high sensitivity.

How can early crack detection impact maintenance costs and operational efficiency?

Early detection can prevent costly failures, saving millions. Small defects can be fixed, extending blade life by decades. Undetected cracks reduce efficiency by altering aerodynamics and increasing fuel use.

What safety protocols are essential during turbine blade inspection?

Safety protocols must handle heat, confined spaces, and hazardous materials. Proper surface prep is key for accurate detection. Documentation ensures compliance and quality assurance.

What are the key differences between field inspection and shop-based inspection for turbine blades?

Field inspection is quick but may miss details due to environmental factors. Shop-based inspection offers controlled conditions and advanced NDT, detecting internal defects. It includes detailed vibration analysis and crack mapping.

How do you determine whether a cracked turbine blade should be repaired or replaced?

Criteria include crack size, location, and propagation risk. Early detection offers repair options like drilling and welding. Replacement is needed for large cracks or those in hard-to-reach areas.

What role does thermography play in turbine blade crack detection?

Thermography shows thermal signatures from cracks, aiding visual inspection. It requires surface prep for accurate results. It’s great for finding internal defects in composite blades.

How do ASME and ISO standards impact turbine blade crack detection procedures?

ASME Digital Collection outlines NDT techniques and inspection standards. ISO standards provide international quality and testing frameworks. These ensure compliance while allowing flexibility.

What are the limitations of visual inspection methods for turbine blade crack detection?

Visual methods can’t find subsurface defects and rely on surface prep. They involve subjective interpretation. Remote visual inspection can access internal passages but depends on training and access.

How does blade vibration analysis contribute to crack detection in gas turbine engines?

Vibration analysis reveals dynamic responses indicating cracks. High-frequency analysis can spot structural changes, even in composites. It detects changes in aerodynamics and vibration.

What factors influence crack propagation rates in turbine blades?

Operating conditions, material, design, thermal stress, and centrifugal forces affect crack growth. Axial and centrifugal configurations have different stress patterns. Understanding these is key for predicting failure and planning maintenance.

How effective is eddy current array technology for steam turbine blade inspection?

Eddy current arrays quickly scan large surfaces with high sensitivity. They are effective for detecting fatigue cracks in high-stress areas. This technology is great for conductive materials and complex geometries.