In steam turbines, seal strips are critical components that control steam flow, prevent leakage, and protect efficiency across high-pressure and low-pressure sections. Over time, these precision-engineered strips are exposed to extreme temperatures, vibration, and erosion—conditions that can wear them down and compromise turbine performance.

When seal strips become damaged or distorted, even minor leakage can translate into significant efficiency losses, increased fuel consumption, and costly downtime. Regular inspection, timely repair, and precise restoration of seal strips are essential to maintain optimal output and prolong the life of a turbine.

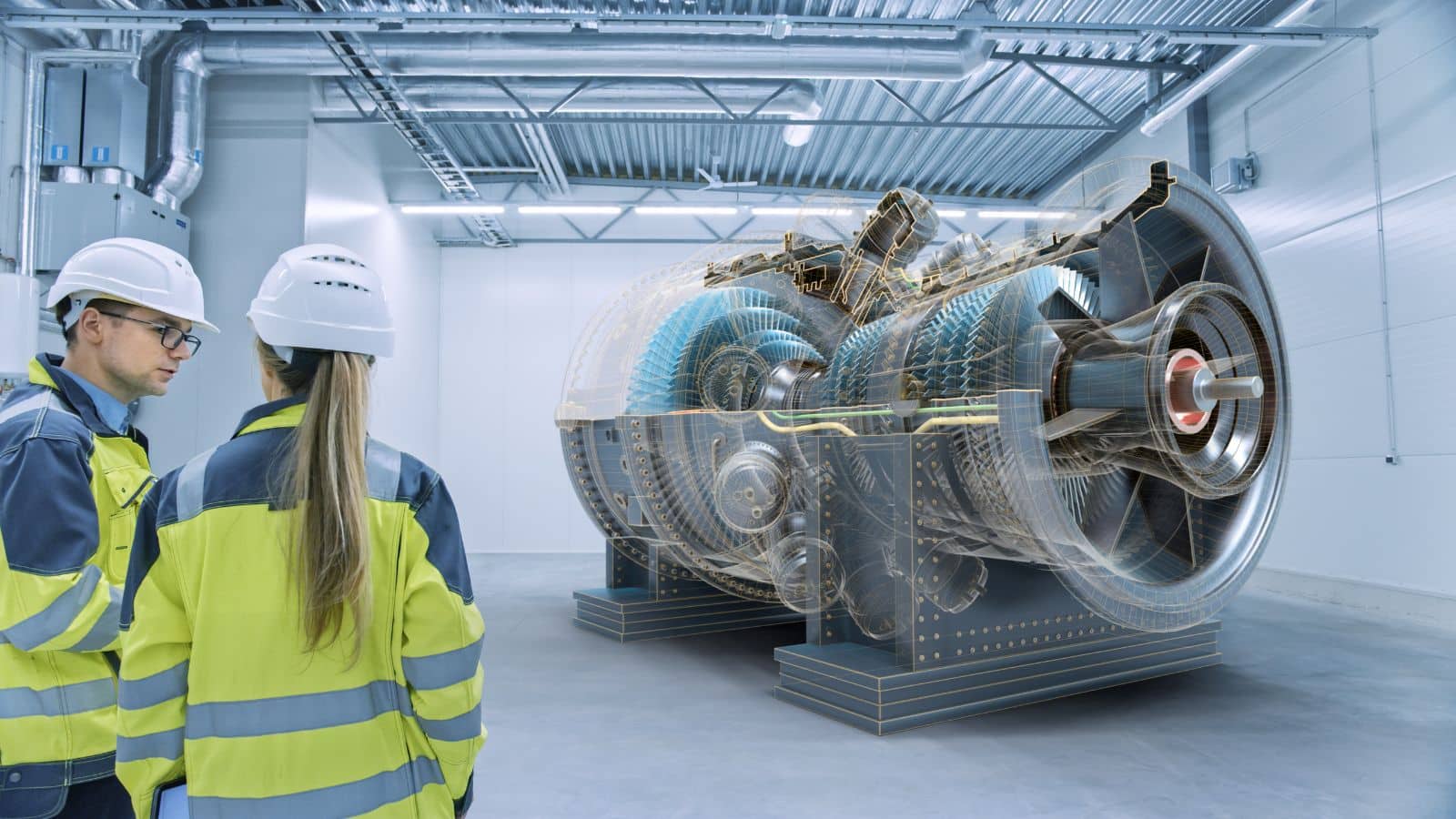

This is where specialized steam turbine seal strip repair services come in. Combining advanced machining, welding, and quality-control techniques, expert repair teams restore sealing surfaces to exact specifications, ensuring turbines operate safely and efficiently. In the following sections, we’ll look at why seal strips matter, common causes of their deterioration, and the methods used to repair them for long-term reliability.

Key Takeaways

- At Allied Power Group we provide nationwide steam turbine repair services from our Houston headquarters

- Our experienced team specializes in precision installation, machining, and welding processes

- We offer 24/7 emergency support to minimize costly downtime during outages

- Our services include working with all major OEMs for replacement parts and system restoration

- Our rigorous quality control standards ensure maximum equipment performance and reliability

- Our comprehensive power services cover routine maintenance through complete overhauls

Understanding Steam Turbine Seal Strips and Their Importance

Steam turbine seal strips are critical for power generation efficiency and reliability in industrial settings. They ensure proper steam flow and prevent energy loss. At Allied Power Group, we recognize the importance of sealing technology in maintaining turbine performance.

Diaphragms use seals to block steam leakage around bucket tips and along the rotor shaft. Damaged seals, like those at the seal tips, reduce efficiency. Regular inspections and replacements of seal strips are essential for optimal performance.

The Function of Seal Strips in Steam Path Efficiency

Steam turbine seal strips act as barriers to direct steam flow through specific paths. They work with stationary and rotating parts to maintain clearance. This prevents steam from bypassing critical energy conversion stages.

Proper seal tooth and packing ring configurations ensure steam follows its intended path. This maximizes energy extraction from the working fluid. When sealing technology is effective, turbine efficiency is maintained.

The interaction between stationary and rotating seals creates multiple sealing points. Each point has a specific role in controlling steam flow. Proper management of these clearances is key to system performance.

Common Causes of Seal Strip Damage and Wear

Several factors contribute to seal strip deterioration, impacting turbine seal integrity. Understanding these causes aids in planning maintenance and preventing failures. Our Houston-based team at Allied Power Group has identified common damage patterns.

The main causes of seal strip damage include:

- Thermal cycling that causes expansion and contraction stress

- Mechanical wear from rotor vibration and contact

- Steam erosion at high-velocity flow areas

- Contamination from foreign particles in the steam

- Corrosion from moisture and chemical impurities

Temperature fluctuations during startup and shutdown cycles stress sealing components. These changes cause materials to expand and contract repeatedly. This leads to fatigue and eventual failure.

Steam leakage increases when seal strips lose their shape or develop gaps. This reduces steam path efficiency and forces the turbine to work harder. Early detection of seal wear prevents extensive damage to surrounding components.

The Impact of Compromised Seal Systems on Turbine Performance

Seal system deterioration has far-reaching effects, impacting power generation operations significantly. Failures in high-pressure and low-pressure stages lead to inefficiencies that spread throughout the turbine. Minor seal degradation often triggers major failures, affecting all rotating equipment.

Damage to seals at the nozzle opening harms turbine performance and efficiency. This is because damaged seals hinder optimal flow from the nozzle to the rotating bucket. Such damage can also lead to mechanical failure of the nozzles, causing severe damage to the rotating buckets.

Efficiency Losses and Steam Leakage Consequences

Steam leakage through damaged seals immediately reduces turbine efficiency, affecting performance stage-to-stage. In low-pressure turbine sections, longer blades are more susceptible to these losses. The turbine must work harder, producing less power due to the pressure drop.

LP turbine steam leakage also causes vibration issues, affecting the turning gear and other critical components. As seals deteriorate, misalignment occurs, leading to uneven wear on rotating equipment. We address these issues early to prevent further problems.

Combined cycle applications face unique challenges with seal failures. Efficiency losses in one turbine stage impact overall plant performance. Disruptions in the steam path accelerate component degradation throughout the system.

Operational Costs and Power Generation Impact

The financial impact of compromised seal systems goes beyond repair costs. Reduced turbine performance leads to increased fuel consumption and lower power output. These losses add up quickly, making seal repairs essential for plant profitability.

Emergency outages due to seal failures can sideline entire combined cycle units for weeks. The lost revenue during these shutdowns often exceeds the cost of proactive seal maintenance. We help facilities avoid these costly scenarios through early intervention and seal system monitoring.

| Performance Impact Area | Efficiency Loss Range | Operational Consequence | Cost Impact Level |

|---|---|---|---|

| High-Pressure Stage Leakage | 2-5% efficiency reduction | Increased fuel consumption | Moderate |

| LP Steam Path Disruption | 5-12% performance loss | Reduced power output | High |

| Combined Cycle Integration | 8-15% system degradation | Plant-wide efficiency loss | Severe |

| Catastrophic Seal Failure | Complete unit shutdown | Emergency outage required | Critical |

At Allied Power Group, we specialize in identifying seal deterioration patterns early. By monitoring turbine performance indicators and conducting regular inspections, we help facilities maintain optimal efficiency. Early intervention prevents major failures, delaying the need for refurbishment, ensuring plant-wide performance.

Allied Power Group’s Steam Turbine Seal Strip Repairs

At Allied Power Group, we excel in advanced steam turbine seal strip repairs. Our Houston facility combines decades of experience with cutting-edge technology. This ensures top-notch solutions for power generation facilities nationwide. Each repair project is unique, requiring tailored strategies for the best results.

Our team has tackled hundreds of seal strip repair projects. From minor adjustments to complete overhauls, we’ve done it all. Recently, we refurbished a 330MW turbine rotor during a scheduled maintenance. We replaced old J-strips with new ones, all precision-machined, in just two weeks.

Advanced Repair Methodologies

Our services cover every aspect of seal strip restoration. We use precision machining for rotors and casings, ensuring exact specifications. Our metallurgical experts apply finite element analysis for effective repair strategies.

When weld repair is needed, we choose the right process for the material and conditions. Our certified technicians perform MIG and TIG welding with specialized filler materials. Post-weld heat treatment ensures stress relief and integrity.

We specialize in diaphragm and nozzle repairs, requiring precise control. Our two-piece assembly reconstruction allows us to rebuild complex seals. These methods extend component life significantly.

On-Site Repair Capabilities vs. Houston Facility Services

Our on-site team offers immediate solutions during outages. They use portable equipment and borescope tools for minor repairs. This approach saves time and reduces costs for simple repairs.

Complex projects, though, benefit from our Houston facility. It has advanced testing equipment and machining centers for challenging repairs. Here, we can rebuild entire assemblies under strict quality control.

The choice between on-site and facility-based repairs depends on several factors. Our engineering team evaluates each project to recommend the best approach. This ensures cost-effectiveness and meets performance and schedule requirements.

Quality Control and Performance Testing

Every repair follows rigorous inspection and repair protocols. Our quality control starts with advanced damage assessment. We document findings and develop detailed repair plans.

Mechanical stress analysis is key to our quality assurance. We verify that repairs can withstand operational loads and thermal cycling. Our testing includes dimensional verification, material property confirmation, and performance validation.

Final inspection ensures that repairs meet engineering specifications. We provide detailed documentation of all work, including material certifications and test results. This approach guarantees optimal turbine performance and extended component life.

Conclusion

At Allied Power Group we are the top name in steam turbine repair services, providing complete solutions to get your equipment running at its best. Our Houston facility brings together years of experience and the latest repair techniques. We handle both moving and stationary parts with great care.

Damage to turbines can really hurt your power generation efficiency. Our team works hard to restore your turbine’s efficiency. We do this through strict quality checks and affordable solutions. Whether it’s an emergency or planned maintenance, we aim to improve your turbine’s performance and extend its life.

Our network covers the whole country, ready to help 24/7 with any turbine issues. This quick response helps keep your operations running smoothly. Our services are designed to meet both urgent repair needs and long-term reliability goals.

We can handle complex repairs at your site or in our advanced Houston facility. Our success in improving steam turbine efficiency is well-documented. We’ve helped many power generation projects achieve their goals.

Choose Allied Power Group for our expertise and commitment to excellence in steam turbine services. We ensure your critical assets run efficiently. Our dedication to quality means reliable performance and a good return on your investment.

FAQ

What are steam turbine seal strips and why are they critical for turbine performance?

Steam turbine seal strips are vital for preventing steam leaks around moving parts. They ensure the steam flows efficiently by maintaining the right gap between the rotor and casing. Properly functioning seal strips are essential for the turbine’s efficiency across all stages, from high to low pressure.

How does Allied Power Group’s Houston facility support nationwide steam turbine repair services?

Our Houston headquarters is the heart of our steam turbine repair services. It houses advanced machine shops and tools for detailed work. We offer 24/7 emergency support, combining controlled environment work with on-site repairs. Our team can handle minor fixes to full overhauls during scheduled downtime.

What are the most common causes of seal strip damage in steam turbines?

Seal strip damage often results from thermal cycling, mechanical stress, erosion, and contamination. Misalignment also accelerates wear. These issues can lead to reduced sealing effectiveness and failure if not addressed.

How do compromised seal systems impact overall turbine efficiency and performance?

Compromised seals cause significant efficiency losses due to increased steam leakage. This affects all turbine stages, leading to higher fuel consumption and reduced power output. It can also cause vibration issues, impacting the entire system’s performance.

What repair techniques does Allied Power Group use for steam turbine seal strip restoration?

We use advanced techniques like precision machining and specialized weld repair. Our methods include diaphragm repairs and two-piece assembly reconstruction. We ensure quality through detailed inspection and analysis, guaranteeing optimal results.

When should seal strip repairs be performed on-site versus at your Houston facility?

Minor repairs are suitable for on-site work with portable equipment. Complex tasks, like precision machining and rebuilds, are best done at our Houston facility. Our controlled environment ensures thorough and precise restoration.

How does Allied Power Group ensure quality control in steam turbine seal repairs?

We follow strict inspection and repair protocols, including mechanical stress analysis and performance testing. Our finite element analysis validates repair strategies. We also perform post-weld heat treatment when necessary, ensuring long-lasting repairs.

What types of sealing technology does Allied Power Group work with?

We handle various sealing technologies, including seal tooth configurations and packing rings. Our expertise spans high-pressure, intermediate, and low-pressure sections, including combined cycle units. We provide tailored solutions for each application.

How quickly can Allied Power Group respond to emergency steam turbine seal failures?

We offer 24/7 emergency support to minimize downtime. Our teams can quickly assess and repair issues on-site. For complex repairs, we can work efficiently during scheduled outages, as shown in our 330MW unit case study.

What is the cost impact of delaying steam turbine seal strip repairs?

Delaying repairs worsens steam leakage and reduces efficiency, increasing operational costs. Stage-to-stage performance degradation affects LP sections more. Early intervention is more cost-effective, preventing extensive emergency repairs and downtime.