Gas turbine rotor repairs are mission-critical operations within the power generation industry. A malfunctioning or degraded rotor can reduce efficiency, cause unexpected outages, and result in substantial revenue loss. This article explores the importance of turbine repair, the damage mechanisms involved, modern inspection technologies, and advanced restoration techniques to extend the life of gas turbine engines.

Key Takeaways

- Gas turbine rotor repairs help avoid costly power plant downtime and extend asset life.

- Advanced diagnostic methods ensure early issue detection before catastrophic failure.

- Specialized welding, balancing, and heat treatment techniques restore turbine performance.

- Compliance with OEM and industry standards is vital to operational safety and regulatory approval.

- Choosing a certified repair facility ensures quality assurance, service agreements, and long-term cost-effective solutions.

Understanding Gas Turbine Rotors and Their Critical Functions

Gas turbine rotors play a pivotal role in the efficient operation of gas turbines widely used across various power plants. These rotors convert thermal energy generated through fuel combustion into mechanical energy. The mechanical energy drives critical components, such as generators and compressors, directly impacting overall plant efficiency and reliability.

A gas turbine rotor integrates the compressor, combustor, and turbine sections, ensuring cohesive functionality across these crucial segments. High-performing gas turbine engines rely on meticulously maintained rotors, where even minor rotor damage can trigger substantial downtime and extensive turbine repair costs.

Basic Components and Materials of Modern Gas Turbine Rotors

Modern gas turbine rotors consist primarily of:

- Compressor Rotor: Responsible for compressing incoming air, ensuring optimal combustion conditions.

- Turbine Rotor: Extracts mechanical energy from high-pressure, high-temperature gases generated in the combustion chamber.

- Central Shaft: Transfers the mechanical energy between turbine and compressor components, enabling seamless power transmission.

Advanced rotors utilize specialized materials, including nickel-based superalloys, titanium alloys, and stainless steels, designed specifically to withstand intense operational environments characterized by high temperatures, mechanical stress, and corrosive atmospheres.

Common Damage Mechanisms in Gas Turbine Rotors

Gas turbine rotors face harsh environments, leading to various damage mechanisms. These can significantly affect their performance and longevity. Identifying and repairing these issues promptly is essential. Understanding these mechanisms is key to effective maintenance and repair.

Thermal Fatigue and High-Temperature Creep

Thermal fatigue arises due to repetitive heating and cooling cycles, causing expansion and contraction stresses that ultimately lead to material cracking. Similarly, high-temperature creep occurs when rotors are subjected to prolonged periods at elevated temperatures, resulting in permanent deformation.

These issues are frequent in industrial gas turbines that operate continuously under rigorous conditions, making routine inspections and timely repairs critical to maintaining operational effectiveness and safety.

Mechanical Wear, Erosion, and Foreign Object Damage

Rotors are prone to mechanical wear resulting from operational stresses and the impacts of foreign objects entering the turbine. Erosion caused by abrasive particles within intake air further accelerates deterioration of rotor surfaces, negatively impacting turbine efficiency.

Power plant operators typically implement stringent filtration and protective measures to mitigate these forms of damage, enhancing rotor life and performance reliability.

Corrosion, Oxidation, and Material Degradation

Exposure to high temperatures and contaminants, including sulfur, sodium, and chloride compounds, leads to significant corrosion and oxidation in rotor materials, weakening structural integrity over time.

Effective corrosion control strategies include specialized protective coatings and surface treatments designed to prevent material degradation, significantly improving rotor longevity.

Diagnostic Methods for Identifying Rotor Issues

Effective diagnostic methods are essential for spotting problems in gas turbine rotors. They allow for quick repairs and reduce downtime. Advanced technologies and proven techniques help operators keep an eye on rotor health. This way, they can tackle issues before they become major problems.

Performance Monitoring and Vibration Analysis

Continuous performance monitoring and detailed vibration analysis effectively identify potential rotor anomalies before significant damage occurs. Implementing live remote diagnostics further facilitates the early detection of issues, reducing turbine outage durations.

These proactive measures are essential for predictive maintenance, allowing plant operators to strategically plan necessary repairs and minimize unexpected operational downtime.

Advanced Inspection Technologies and Techniques

Modern rotor inspections leverage sophisticated non-destructive testing (NDT) techniques such as ultrasonic, eddy current, magnetic particle, and phased array inspections. These advanced inspection methods accurately detect internal and surface defects, significantly improving the precision of rotor life assessments.

Comprehensive Gas Turbine Rotor Repairs Process

The rotor repairs process for gas turbines is meticulous and step-by-step. It aims for the highest quality and reliability in the repaired components. It starts with an initial assessment and documentation of the rotor’s condition. Then, careful disassembly procedures are followed to access the internal components.

Initial Assessment, Documentation, and Disassembly Procedures

Rotor repairs begin with detailed initial assessments to document rotor conditions accurately. Following this, precise disassembly procedures separate the turbine rotor and compressor unstack, facilitating detailed component evaluations.

Comprehensive documentation during these phases supports accurate engineering analysis and repair planning, critical for effective rotor restoration.

Non-Destructive Testing and Damage Mapping

The repair process incorporates advanced non-destructive testing techniques to detect hidden defects. Damage mapping generated from these tests guides targeted repair strategies, enhancing repair accuracy and reducing costs.

Engineering Analysis and Repair Strategy Development

Rotor life assessment forms the foundation of the engineering analysis stage, allowing repair specialists to develop customized repair strategies tailored specifically to each rotor’s unique condition. These strategies aim to restore rotor functionality and extend service life significantly.

Allied Power Group offers complete inspection and repair solutions from their state-of-the-art service center, ensuring timely interventions that restore turbine performance.

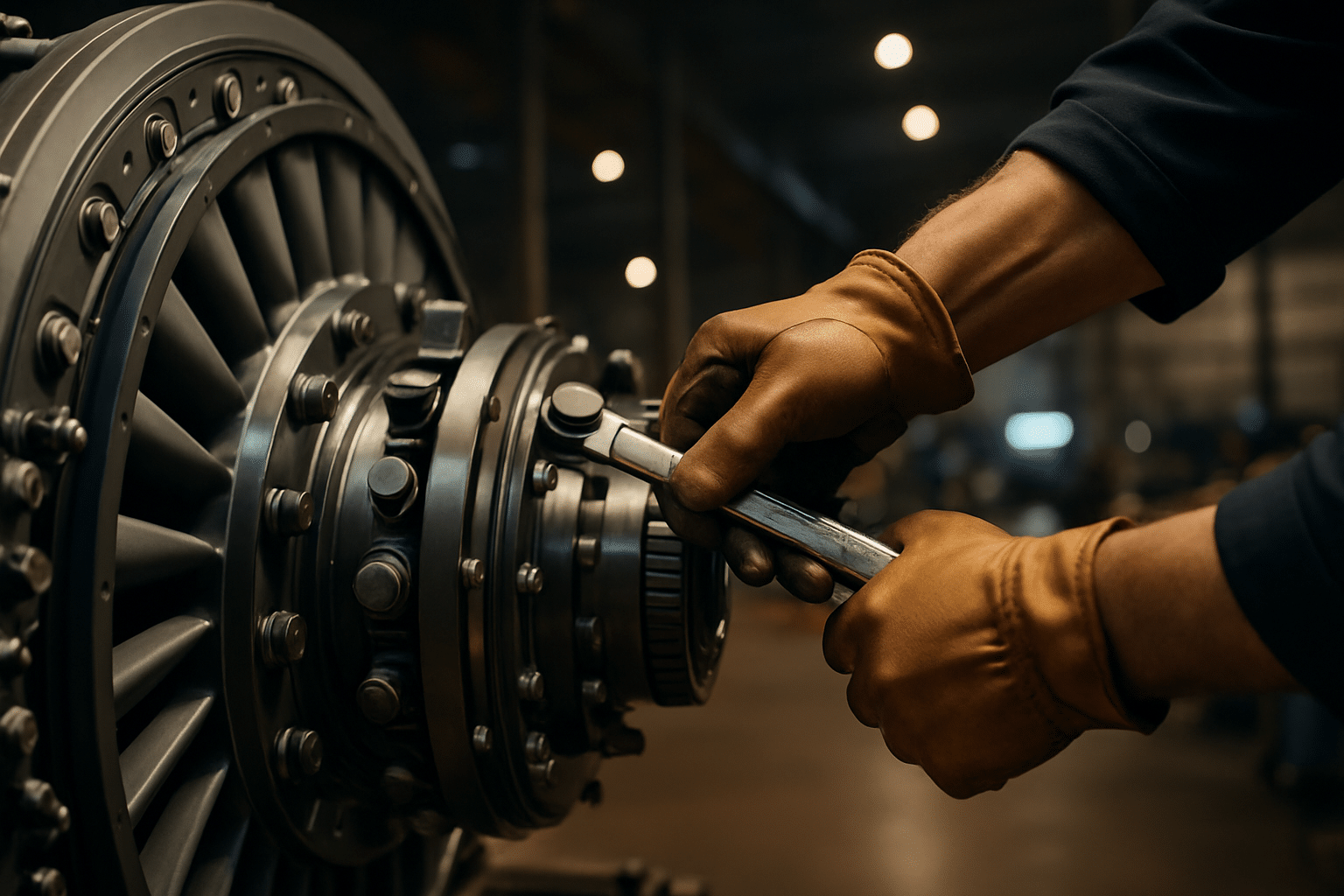

Advanced Repair Techniques for Gas Turbine Rotors

Specialized repair techniques are used to restore gas turbine rotors to their peak condition. These methods include welding, material deposition, precision machining, grinding, dynamic balancing, and heat treatment. They help restore the rotor’s material properties, extending its lifespan and boosting performance.

Specialized Welding and Material Deposition Methods

Precision welding and material deposition technologies, including laser cladding and electron beam welding, effectively repair rotor damage caused by erosion, cracks, and mechanical wear. These advanced techniques offer high-precision restoration, significantly enhancing rotor performance and reliability.

Precision Machining, Grinding, and Dynamic Balancing

Precision machining and grinding restore rotor dimensions and surfaces accurately, while dynamic balancing optimizes rotor balance, reduces vibrations, and enhances overall operational stability.

Proper rotor balancing is crucial for maintaining turbine efficiency, minimizing mechanical stress, and prolonging rotor lifespan.

Heat Treatment Processes and Material Property Restoration

Advanced heat treatment processes, including stress relieving, annealing, and precipitation hardening, restore rotor material properties degraded by thermal fatigue and operational stresses. These treatments are essential for ensuring the rotor components perform effectively under extreme operating conditions.

Blade and Vane Repair Considerations

Gas turbine blade and vane repair are vital for rotor maintenance. These parts face extreme temperatures, pressures, and stresses. Proper repair extends rotor life and boosts turbine performance.

Airfoil refurbishment is key in blade and vane repair. It aims to restore the aerodynamic profile. This involves precision grinding, welding, and machining to rebuild the airfoil. Coatings like thermal barrier and erosion-resistant ones are applied to protect and enhance durability.

Root attachment repairs are critical in blade and vane maintenance. The root ensures the component’s secure attachment to the rotor. Specialized welding, like electron beam or laser cladding, is used to repair and restore structural integrity.

Clearance Optimization

Accurately optimizing clearances between blades, vanes, and rotor sections significantly improves turbine efficiency by reducing aerodynamic losses and enhancing flow stability.

Such precise adjustments require expert skills and specialized equipment available only at advanced turbine repair facilities.

Quality Assurance and Certification in Rotor Repair

In the realm of gas turbine rotor repairs, quality assurance and certification are of utmost importance. Reputable repair facilities strictly adhere to industry standards, OEM requirements, and regulatory compliance. This dedication ensures that repaired rotors not only meet but often exceed the original specifications. Such commitment guarantees reliable performance and extends the service life of the rotors.

Repair facilities implement a detailed quality management system that covers every step of the repair process. This includes:

- Adherence to ISO 9001 and AS9100 quality standards

- Compliance with OEM repair manuals and service bulletins

- Utilization of certified materials and processes

- Employment of highly skilled and trained technicians

Industry Standards, OEM Requirements, and Regulatory Compliance

Meeting stringent industry standards, OEM specifications, and regulatory compliance is essential in rotor repairs. Allied Power Group’s repair specialists ensure that all rotor repairs exceed these rigorous benchmarks.

Quality assurance protocols include rigorous testing, ensuring rotor repairs deliver reliable, safe, and compliant performance under diverse operational conditions.

Testing, Validation, and Documentation Protocols

The final stages of rotor repairs involve comprehensive testing and validation processes to confirm operational integrity. Detailed documentation protocols ensure that all repairs meet defined quality and performance standards, providing operators with assurance and full compliance records.

Table: Comparison of Gas Turbine Rotor Repair Methods

| Repair Method | Applications | Benefits |

|---|---|---|

| Specialized Welding | Cracks, erosion | Restores structural integrity |

| Precision Machining | Dimensional accuracy | Improves rotor efficiency |

| Heat Treatment | Material degradation | Extends material life |

Conclusion

Gas turbine rotor repairs are critical to ensuring sustained turbine efficiency and reliability. Allied Power Group provides comprehensive turbine services, including cutting-edge diagnostic tools, advanced repair methodologies, and stringent quality assurance practices. Their service center is equipped for full-service rotor reconditioning, rotor exchange options, and full rotor evaluations, minimizing downtime and offering cost-effective solutions.

In addition to gas turbine repair, Allied Power Group also supports steam turbine repairs and overhauls, offering tailored solutions for steam and gas turbine systems. This dual capability allows them to service a broader range of assets, helping operators extend the life of their equipment.

Their complete portfolio of products and services includes gas and steam turbine parts, rotor modifications, and long-term service agreements. These solutions are designed to extend the life of critical components while optimizing performance and maintaining regulatory compliance.

“Superior rotor repair solutions are integral to achieving maximum efficiency and operational reliability,” emphasizes Allied Power Group. Their comprehensive expertise in rotor modifications, life extension, and balancing uniquely positions them to address a wide range of gas turbine rotor needs.

Choose Allied Power Group to confidently manage your gas turbine maintenance and repair requirements, ensuring unparalleled operational reliability, regulatory compliance, and performance excellence.