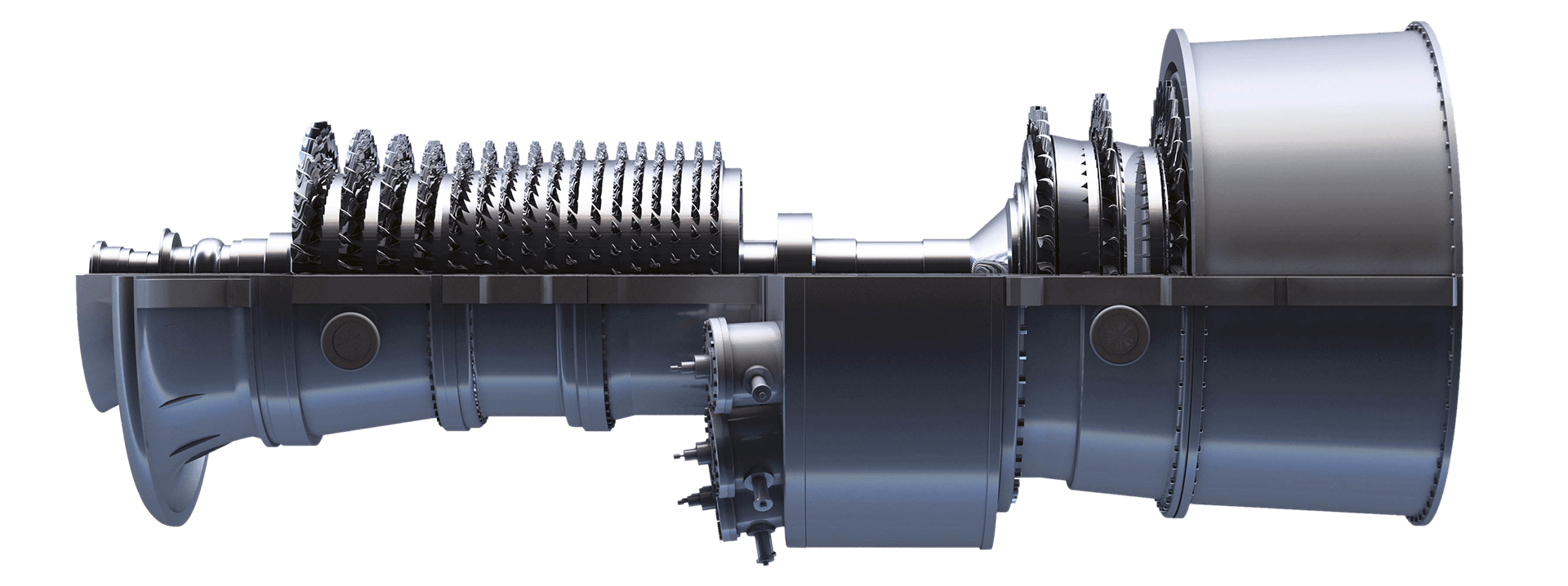

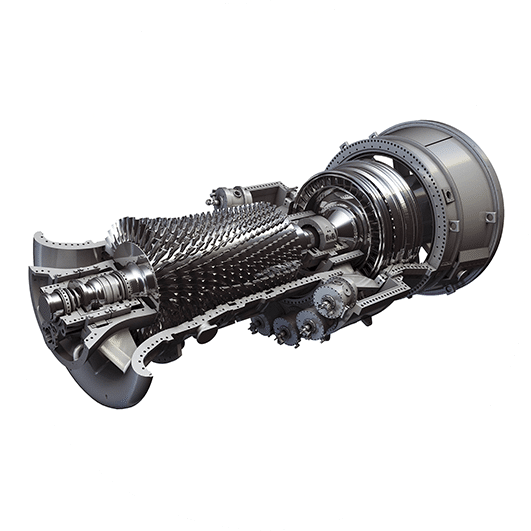

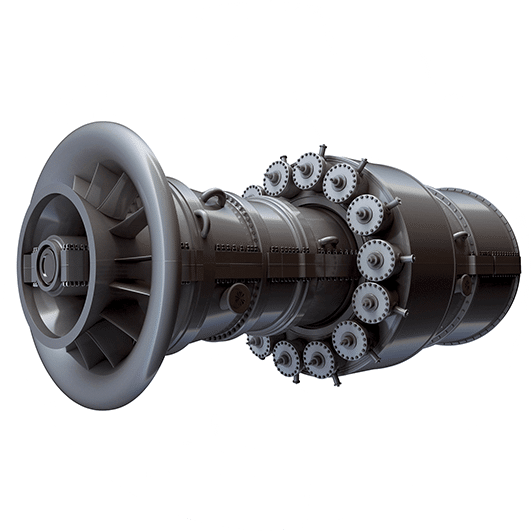

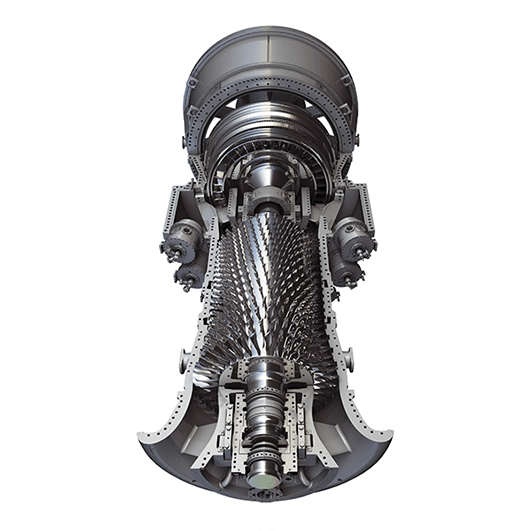

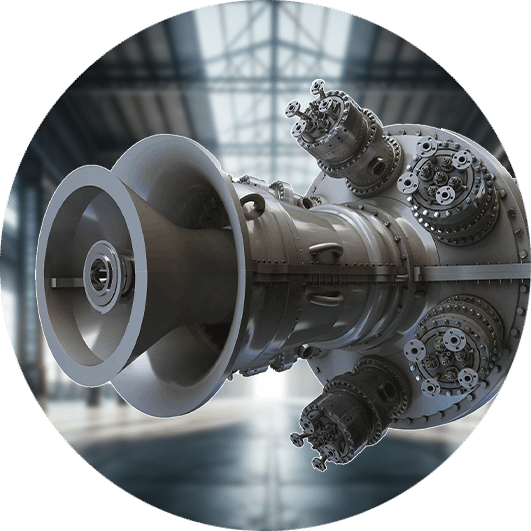

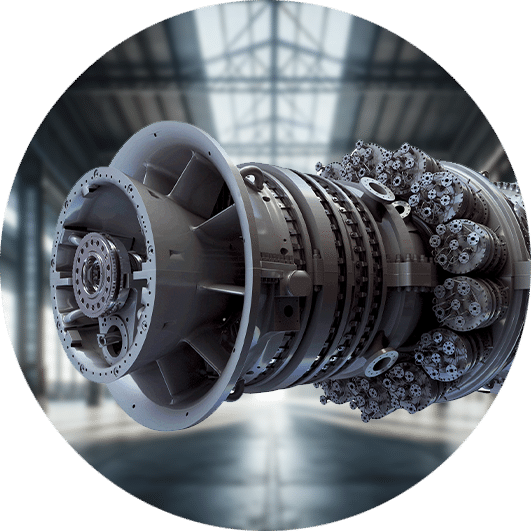

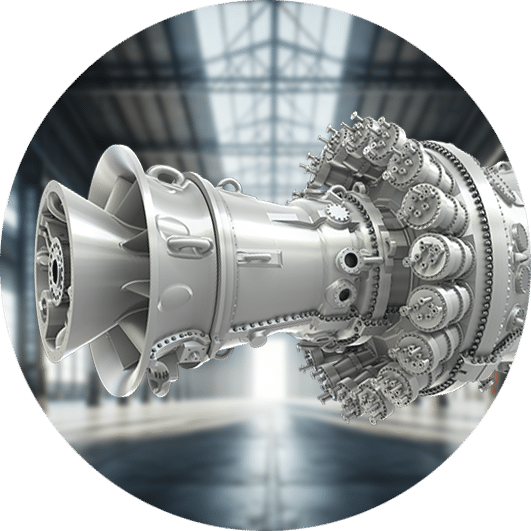

GE Frame 9E Gas Turbine Details

The GE 9E Turbine was introduced in the market a few years ago. However, it still remains one of the top gas turbines for multiple reasons, starting from its robust construction to its versatility, reliability, and longevity. It can be a great option for those looking forward to reducing their electricity costs. Here are some of the features that make the Frame 9 Gas Turbine one of the best options available in the market within its category:

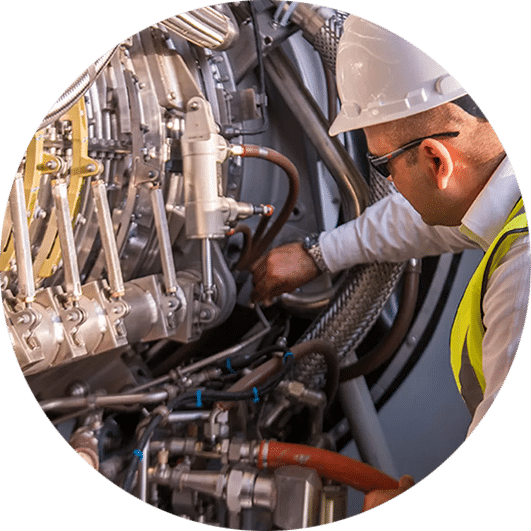

Field & Shop Repair Services

In the Field:

Our experienced field service teams provide 24/7 coverage for GE 9E gas turbines around the world. We handle combustion tuning, alignments, mechanical repairs, borescope inspections, and emergent outage support with a safety-first approach and quick response times.

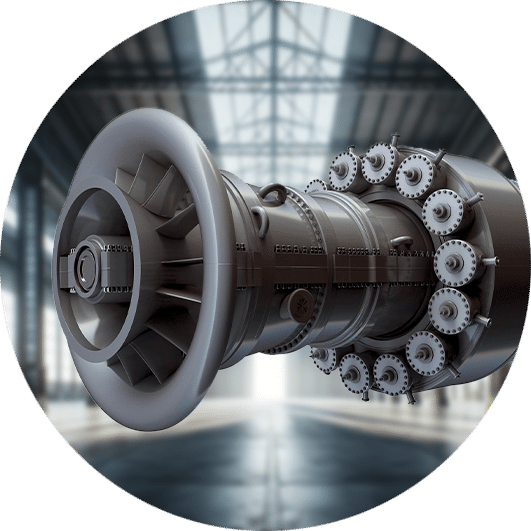

In the Shop:

Our fully integrated Houston facility is equipped for in-depth rotor repairs, machining, weld restoration, and advanced part coatings—all under one roof. This single-source approach ensures quality control, accelerated turnaround, and minimized handling risk for your critical components.