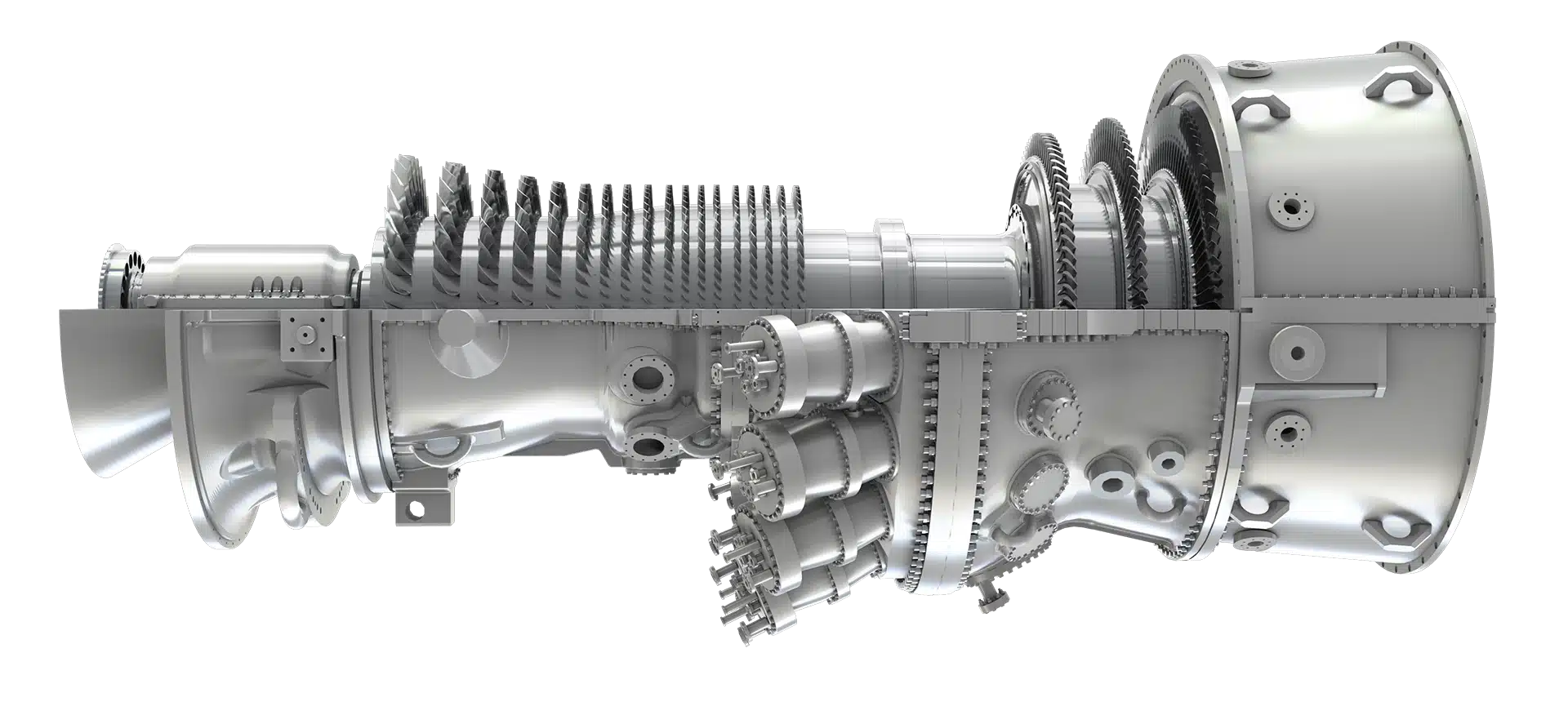

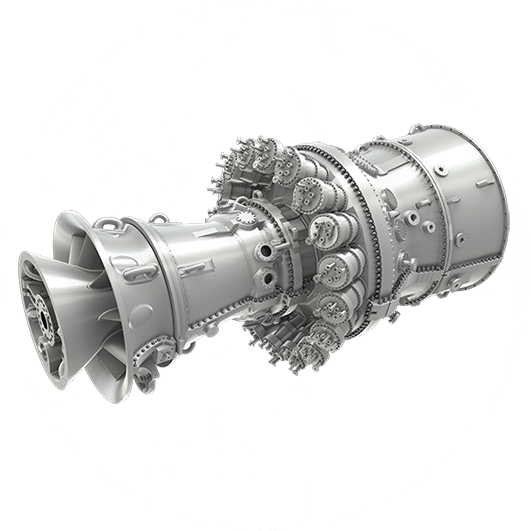

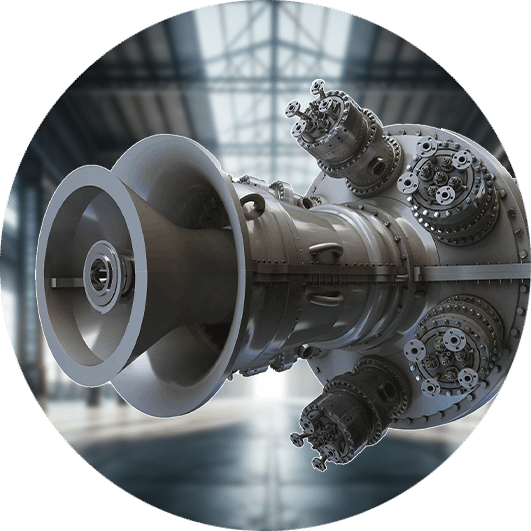

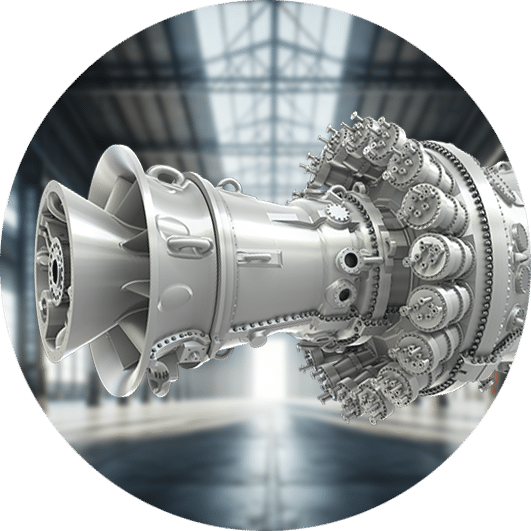

9F Repair & Service Capabilities

Our MRO program for GE 9F turbines is designed to meet the demands of high-output combined-cycle and base load applications. We address common failure modes and wear points with proven processes and advanced tools to ensure reliability, efficiency, and compliance.

Field and Shop Repair Services – Fast, Integrated, and Built for Uptime

Allied Power Group provides both on-site field service and in-house shop repair solutions for GE 9F turbines—ensuring rapid response, complete control, and consistent quality no matter where your turbine needs support.

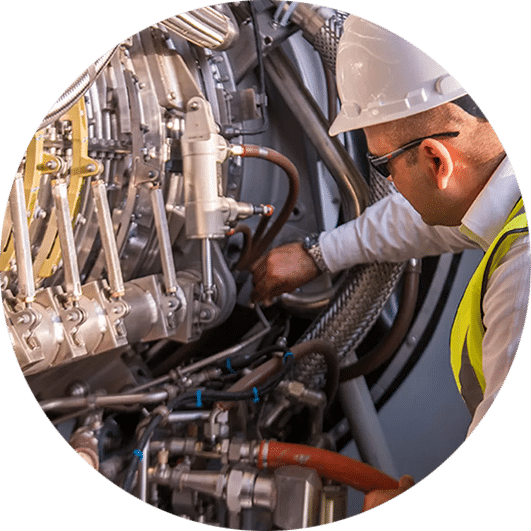

On-Site Field Services

Our expert field crews are available 24/7 to support planned outages and emergency situations. With deep experience in GE 9F systems, we deliver fast mobilization and efficient service that reduces downtime and protects critical operations.

Common field services include:

-

Mechanical troubleshooting and diagnostics

-

Turbine alignments and adjustments

-

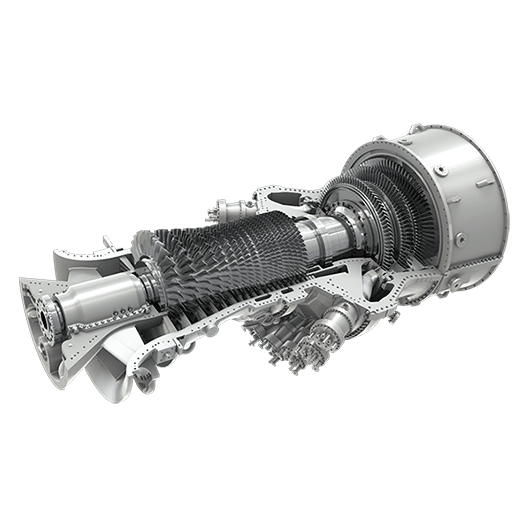

Combustion system tuning and inspection

-

Emergency outage response and component replacement

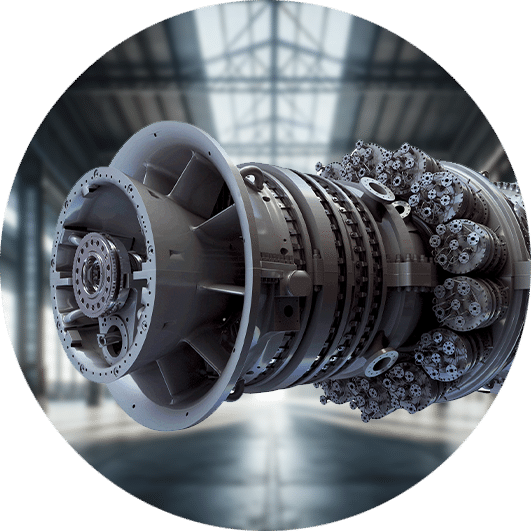

In-House Shop Services

At our Houston-based facility, we handle full-scope repairs with advanced equipment and rigorous QA standards. From welding and machining to coating and balancing, we complete complex turbine repairs under one roof—accelerating turnaround and ensuring precision from start to finish.

Our shop capabilities cover:

-

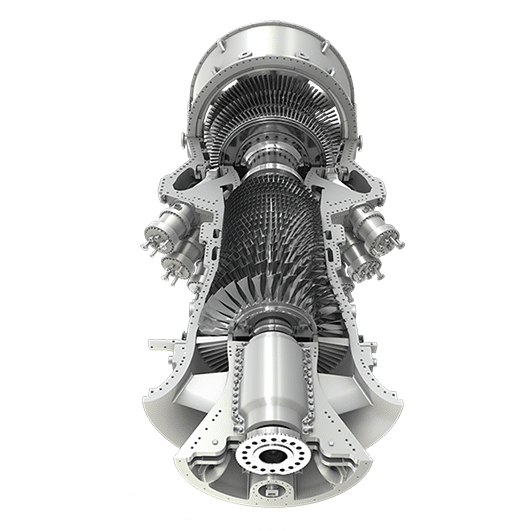

Rotor and hot gas path component rebuilds

-

Casing and diaphragm weld repairs

-

Balancing, NDE, and dimensional verification

-

Advanced coatings for thermal protection and durability

Whether on-site or in-shop, Allied Power Group delivers the expertise and infrastructure you need to keep your GE 9F turbine running at peak performance.