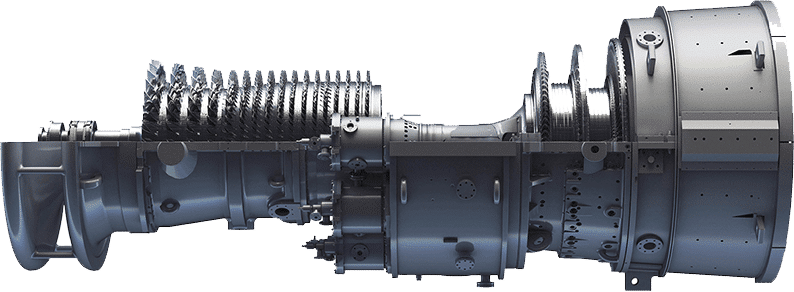

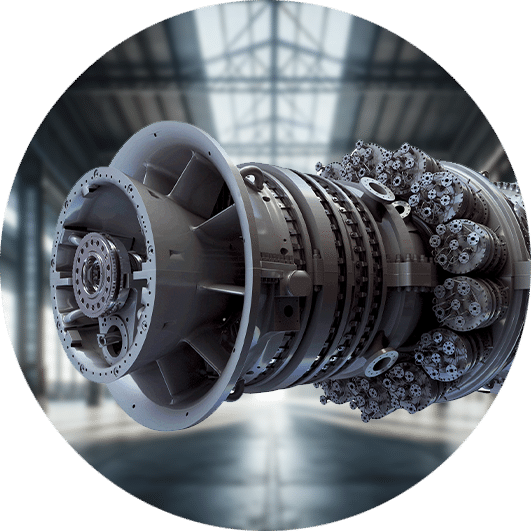

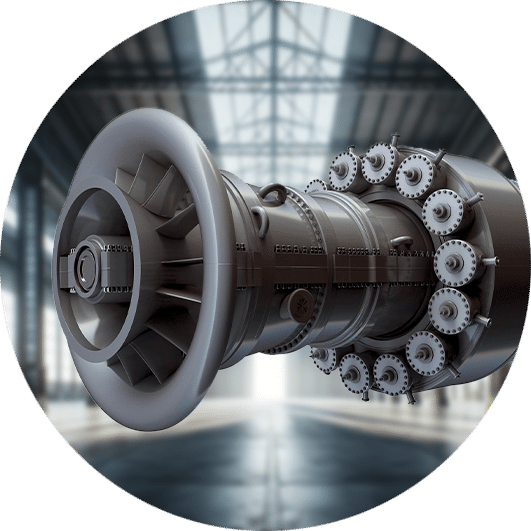

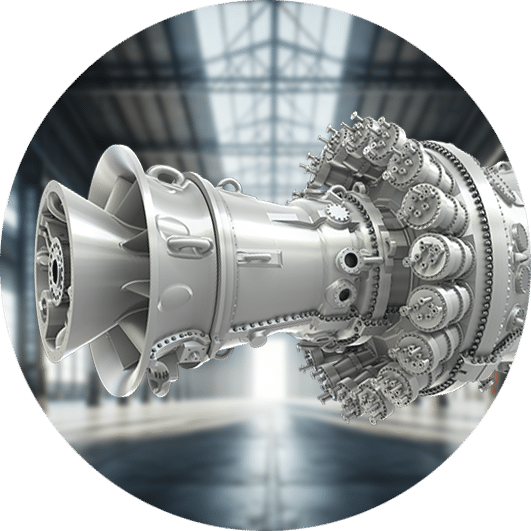

GE Frame 5 Gas Turbine Repair Services

Restoring Legacy Power—Reliable Repairs for GE Frame 5 Units

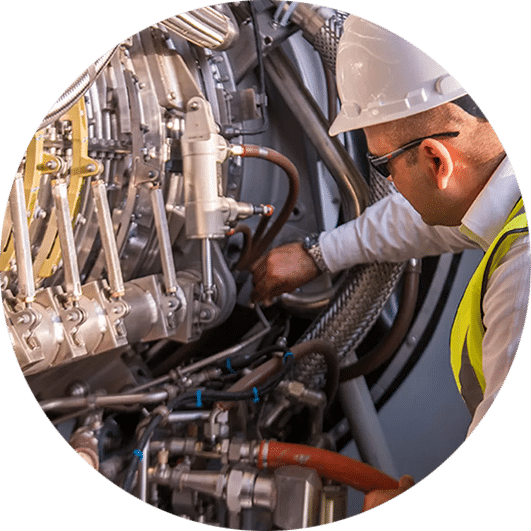

Allied Power Group delivers expert repair, restoration, and field service solutions for GE Frame 5 gas turbines—an industry workhorse known for its rugged durability and widespread global use. Whether you operate a base-load power plant or remote site generator, our team understands the critical role the Frame 5 plays in your operation. We provide cost-effective, high-precision repairs that extend unit life, improve output, and avoid costly OEM delays. From rotor overhauls to combustion system upgrades, we restore your Frame 5 turbine with the quality and speed you need to stay online and on budget.150+

GE Frame 5 Buckets Repaired

115+

GE Frame 5 Nozzles Repaired

60+

GE Frame 5 Combustion Liners Repaired

50+

GE Frame 5 Transition Pieces Repaired