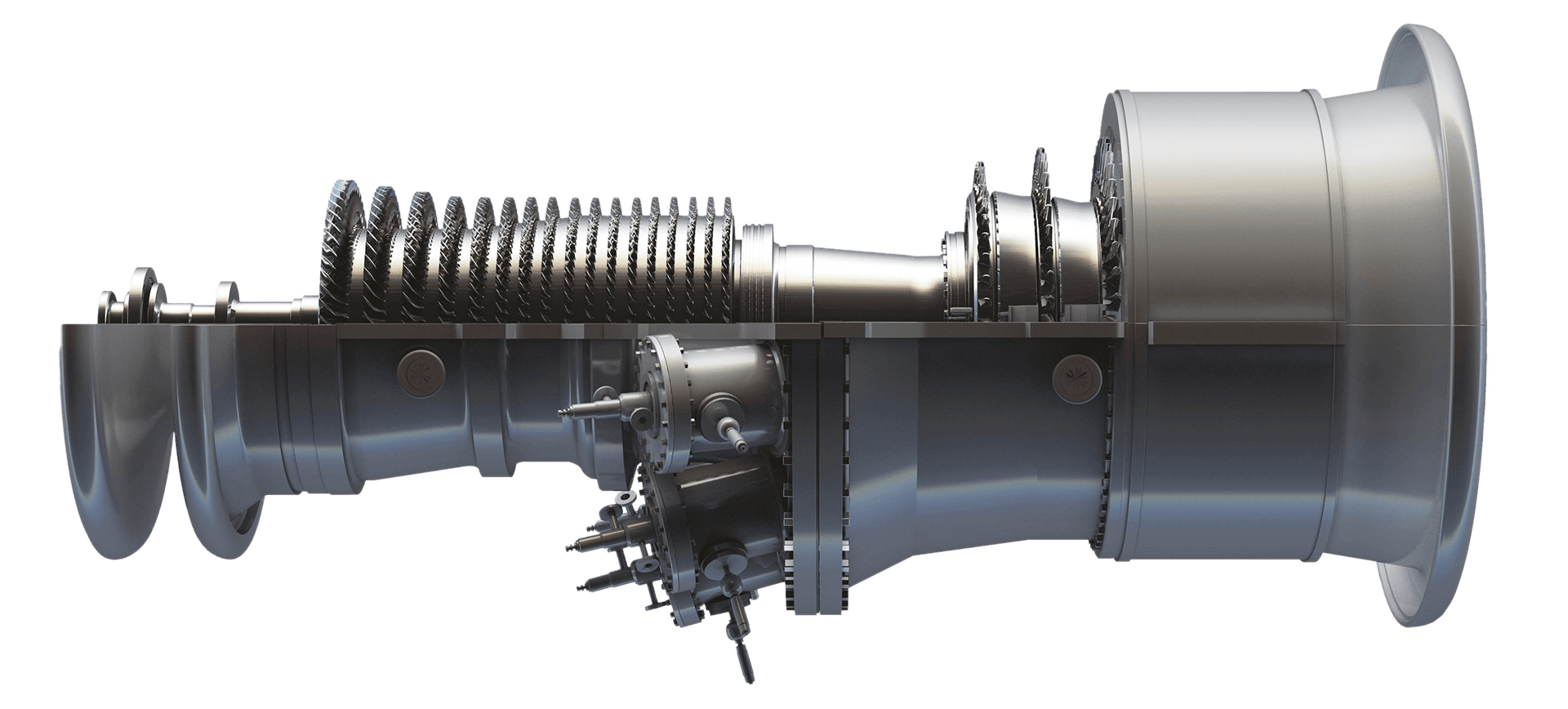

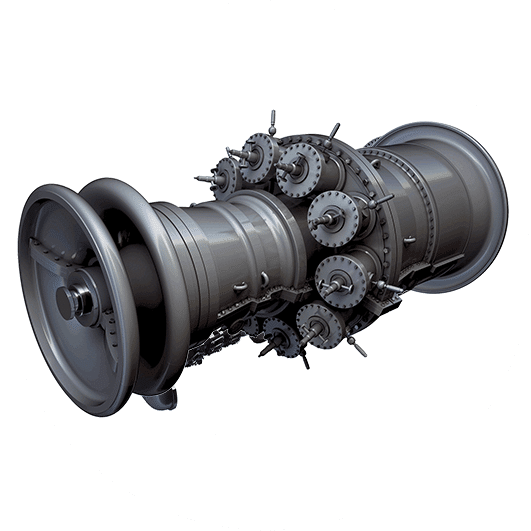

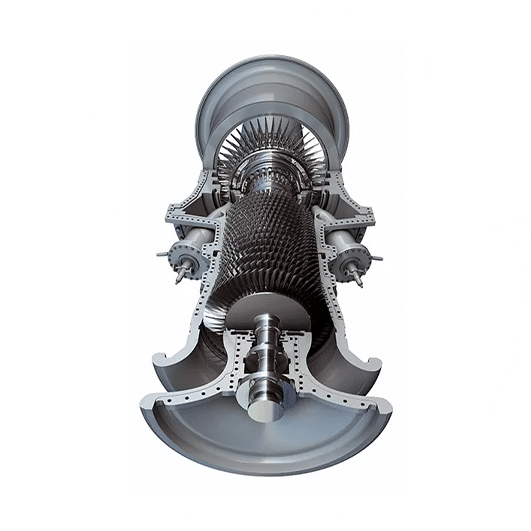

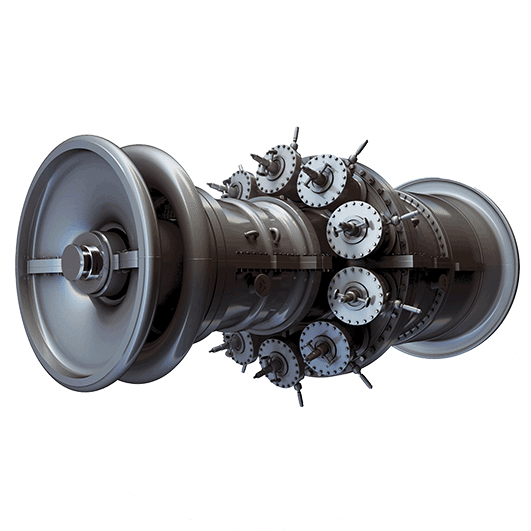

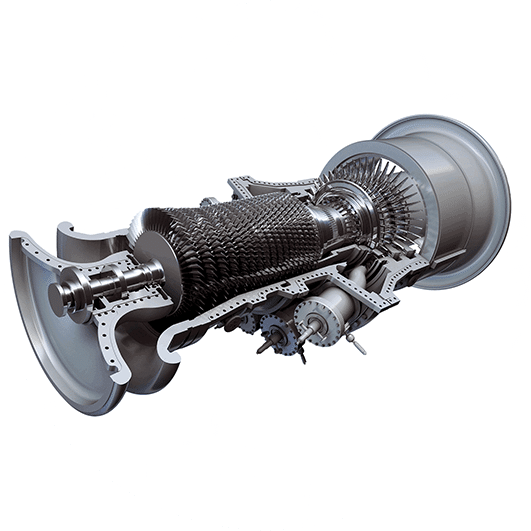

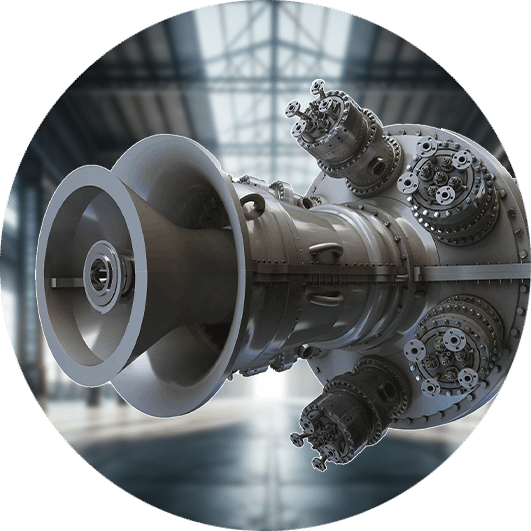

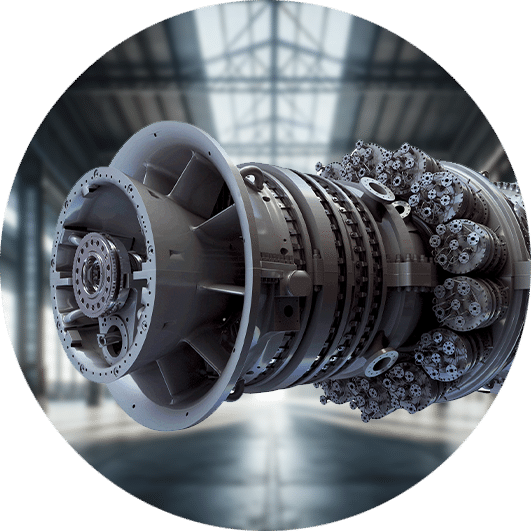

GE Frame 6B Gas Turbine Repair

Proven Repair Solutions for GE Frame 6B Turbines—Legacy Power, Optimized Performance

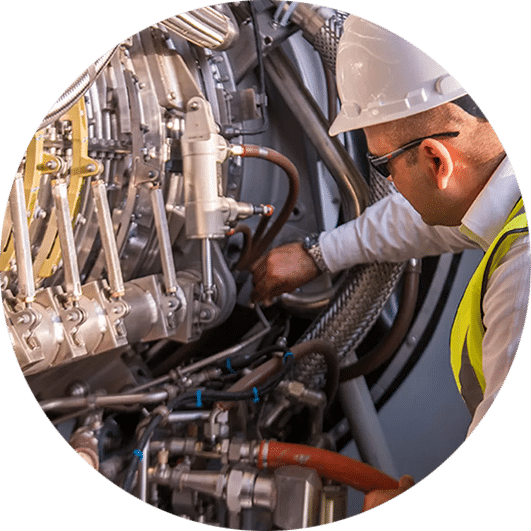

At Allied Power Group, we specialize in extending the life and improving the performance of GE Frame 6B gas turbines. Known for their versatility and long service life, 6B units are still widely used across industrial and utility operations. We provide full-scope, engineered repair solutions that address thermal fatigue, mechanical wear, and age-related degradation—without the delays or high costs of OEM options. From rotor rebuilds and combustion system upgrades to structural repairs and life extension engineering, we restore your Frame 6B to reliable operating condition—safely and efficiently.90+

GE Frame 6 Buckets Repaired

50+

GE Frame 6 Nozzles Repaired

55+

GE Frame 6 Transition Pieces Repaired

25+

GE Frame 6 Shroud Blocks Repaired