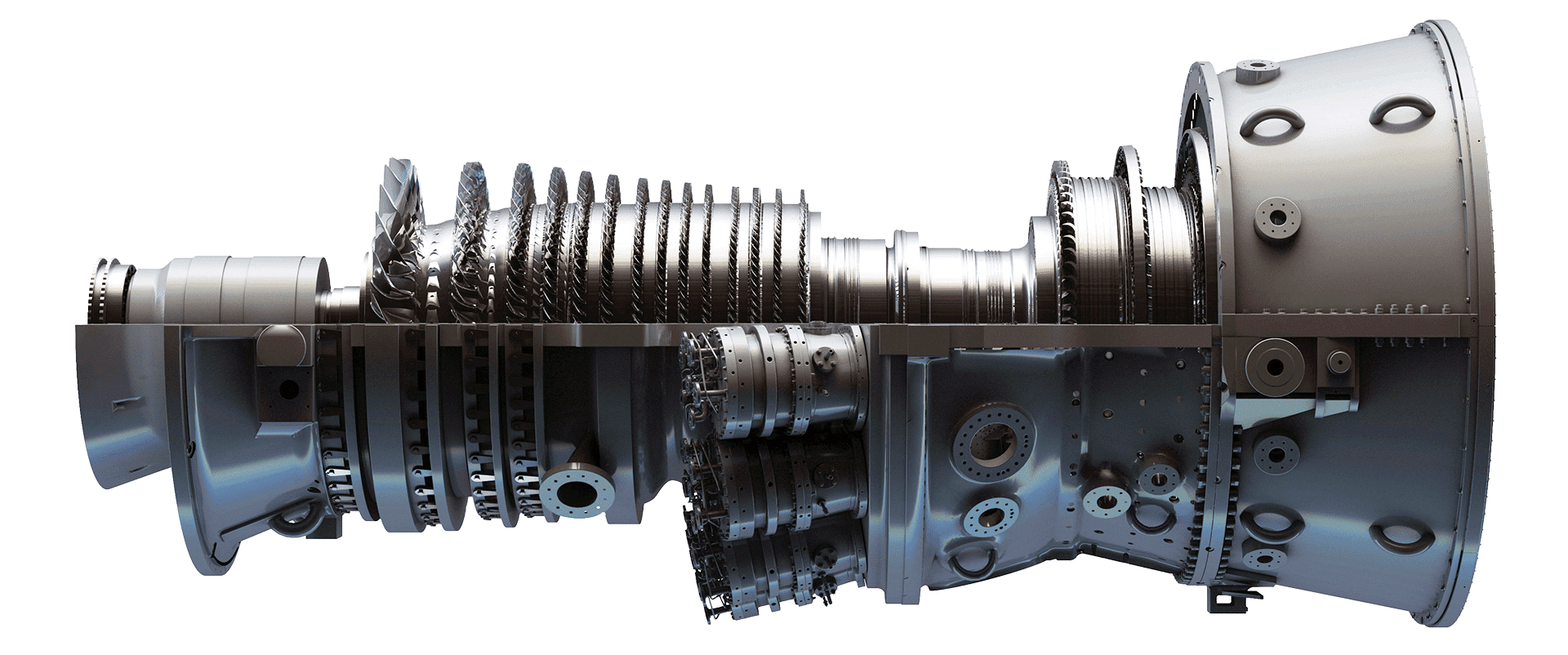

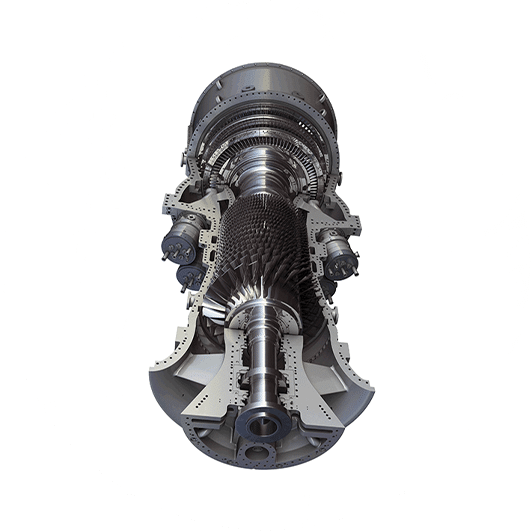

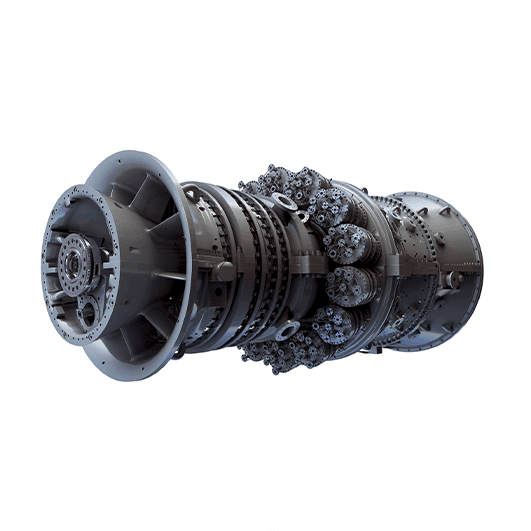

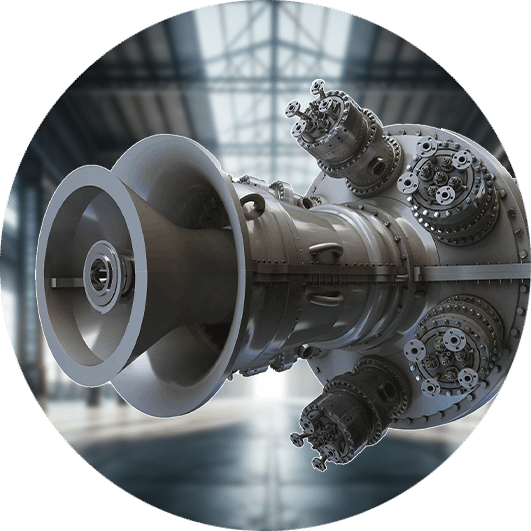

GE Frame 7F Gas Turbine Repair Services

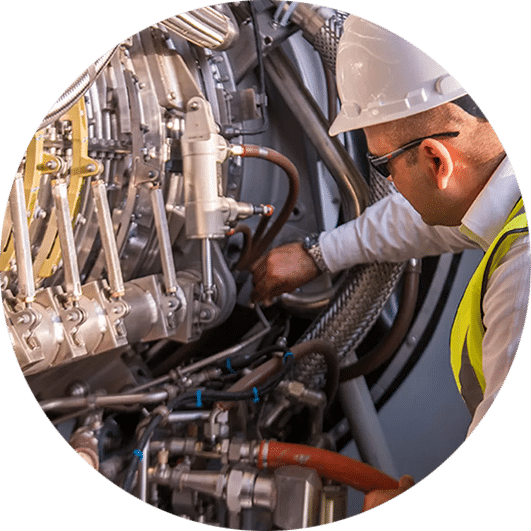

High-Performance Repairs for GE 7F Turbines—Engineered to Restore, Built to Last

Allied Power Group delivers precision repair and restoration services for GE Frame 7F gas turbines—one of the most advanced and high-output machines in combined-cycle and peaking power applications. Known for their efficiency and complexity, 7F units require expert handling, rapid turnaround, and engineering-backed solutions. Whether you’re facing wear in the hot gas path, planning a full rotor overhaul, or seeking an alternative to OEM pricing, we provide a turnkey approach that restores reliability, extends asset life, and reduces outage duration.1,000+

GE Frame 7 Buckets Repaired

760+

GE Frame 7 Nozzles Repaired

800+

GE Frame 7 Shroud Blocks Repaired

825+

GE Frame 7 Combustion Liners Repaired