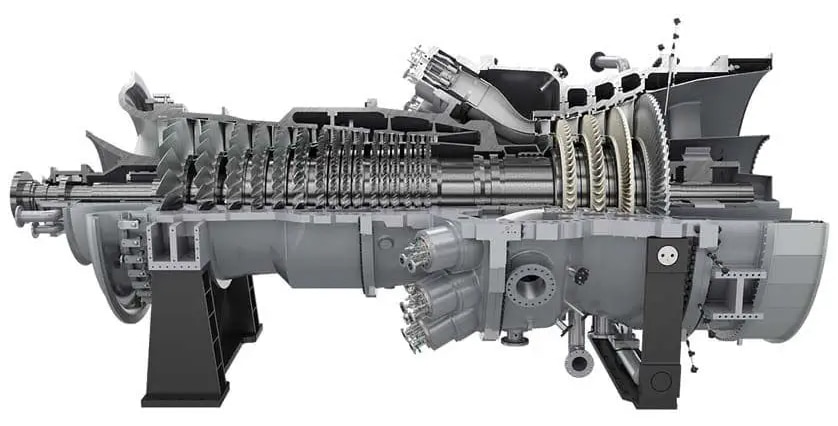

Siemens 501 / D5 / D5A Gas Turbine Repair Services

Full-Scope Repairs for Siemens 501 / D5 / D5A Turbines — Fast Turnaround, OEM-Alternative Precision

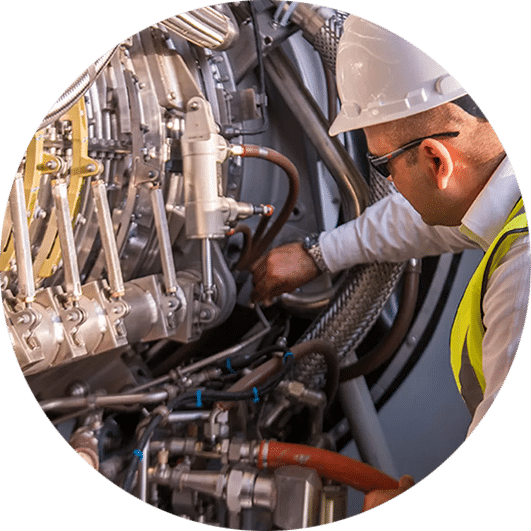

Allied Power Group delivers expert repair, restoration, and engineering solutions for Siemens 501 / D5 / D5A gas turbines. These robust units are used extensively in both industrial and utility-scale power generation—but over time, components degrade due to high temperatures, pressure cycles, and mechanical wear. Whether you’re facing a planned outage or an unexpected failure, we provide a cost-effective, high-precision alternative to OEM repair. From hot gas path refurbishments to rotor rebuilds and combustion tuning, our fully integrated approach ensures your 501 /D5 / D5A turbine returns to peak performance—safely, quickly, and affordably.

140+

Siemens 501-D5A Blades Repaired

155+

Siemens 501-D5A Vanes Repaired

120+

Siemens 501-D5A Ring Segments Repaired

125+

Siemens 501-D5A Nozzles Repaired