Component Coatings

Turbine components though resilient are exposed to extreme operating conditions, such as high temperatures, corrosive environments, and physical damages.

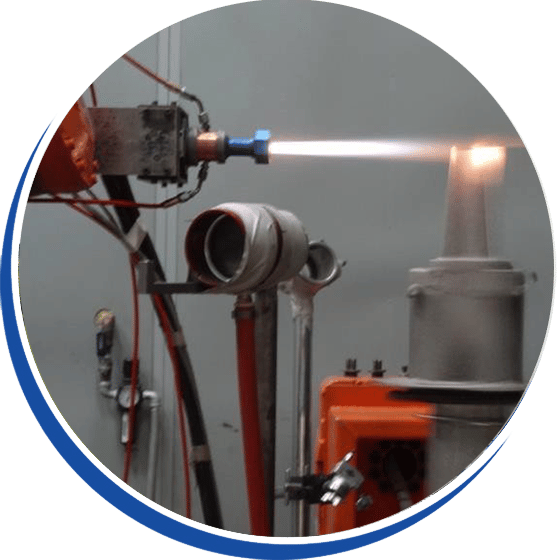

APG’s on-site component coating services reduce outage time and damage risks when shipping large industrial components to an off-site facility. We use high-temperature oxidation and corrosion coatings that help the components withstand high temperatures and other extreme chemical attacks while increasing the turbine's efficiency.

A comprehensive review of the coating on your unit may reveal opportunities to gain unit reliability. These gains can be in the increased repairability of the parts, extended parts life and increased outage intervals.

- Rotors corrosion coating and anti-rock coatings can extend the life of the parts.

- Combustion systems coating can be applied to reduce wear due to high temp., reduce oxidation and reduce the impact of interface wear.

- Turbine section coatings typically allow for the reduction of surface metal temperatures and the impact of oxidation on the parts.

- Thermal barrier coatings (TBC) are typically applied to prevent heat exchange and protect against thermal fatigue and other related issues.

- Abradable coatings reduce the risk of physical wear and tear when moving blades comes in contact with the turbine casing.

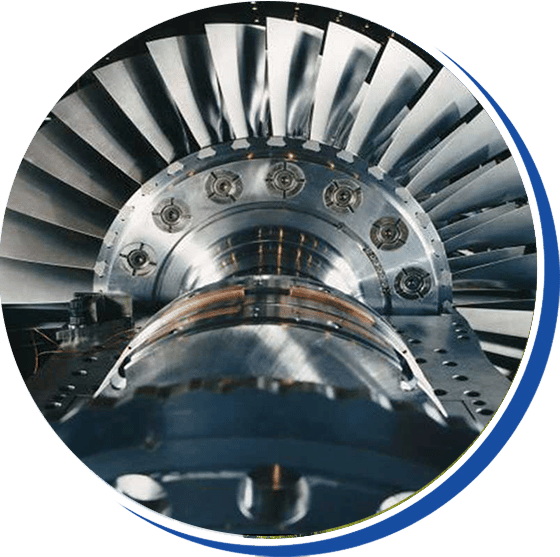

Compressor

Our extensive experience on custom solutions, modifications and repairs allows us to support all applicable OEM technical recommendations on 7FA, 7EA and Siemens/Westinghouse frame compressors. We specialize in repairing compressor issues involving clashing, stator shim elimination, case slippage, stator vane rock, blade tip rock, spacer migration, R17 replacement, and a complete line of compressor rotor shop support. We also have a robust shim elimination program. We can supply and install our own shrouded S17 that is an upgrade to the OEM supplied solution.

For more than 10 years, APG has extended its expertise in repairing hot gas path and combustion components for the Alstom gas turbine fleet. From ALSTOM GT11 compressor repairs to ALSTOM GT11 vane carrier repairs, and beyond. Currently, we are providing comprehensive repairs and rehauling for GT11 D4, D5, and N1 gas turbine models in the power generation, oil & gas and industrial markets.

Instrumentation Upgrades

Throughout our history, we have developed solutions to improve IGT reliability and availability with instrumentation upgrades. There are many opportunities on older frame units to increase reliability with instrumentation upgrades to a unit. This can include bearing metal thermocouple, vibration systems and thermocouple upgrades to allow for replacement without disassembly, flux probes to bus couplers including changes from switches and gauges to transmitters to name a few. We use noble metal thermocouples (available in Type B, R, and S) which can withstand extreme temperatures without affecting the results. The highly accurate and stable results make noble metal thermocouples better than base metal thermocouples for generating sustainable power for years.

Parts modifications

During the repair cycle, there are a number of modifications we offer to increase the reliability of the unit. With unparalleled expertise, we specialize in transition piece, cap and liner assemblies for Frame 6B, 7B, 7E/EA, 7FA +EL, and 9E GE Gas Turbines. The modifications include upgrading the materials used for manufacturing parts for high resilience against extreme temperatures, corrosion, etc., redesigning the turbine blades to improve airflow or accommodating evolving requirements of the output power. The ultimate aim is to redesign parts so as to extend the life of the equipment and improve its overall performance. Thus improving the reliability and availability of gas turbines.

WORKING TOWARDS UPGRADING IGT’S RELIABILITY AND AVAILABILITY SINCE 2005

APG is committed to maximising the availability, reliability and efficiency of industrial gas turbines for sustainable power generation.

At the very core, Allied Power Group (APG) is working as per the four principles:

Advancing The Monitoring Diagnostics

We deploy sophisticated technologies that enhance the turbine’s health monitoring capabilities and risk management practices. From supporting sustainable power generation to preventing expensive power outages, we are here to make a difference.

Leading the Change

Allied Power Group (APG)’s top brass brings a wealth of industry experience to support the improvement of reliability and availability of the latest gas turbine models and makes. From forging strategic partnerships to engineering innovative solutions, we are carving a niche for ourselves.

Emerging Technology Trends

Allied Power Group (APG) engineers' technology solutions for enhancing reliability/availability upgrades. Includes using advanced materials and noble metal coatings, hot gas path inspection, and non-destructive testing. Driving value to your fleet of industrial gas turbine plants.

Partner Growth

Allied Power Group (APG) is aimed at providing our power generation clients with best-in-class service. We have joined hands with Eta Technologies and Nexgen Advanced Fuel Systems to name a few. We are working with GE and Siemens and exploring strategic partnerships in emerging economies.

Frequently Asked Questions

- Erosion resistance coatings that prevent loss of material due to mechanical interaction between compressor blades and fluid ( or solid) particles.

- Thermal barrier coatings (TBC) are applied to protect high-pressure turbine blades and other hot-section components against thermal fatigue and other related issues.

- Oxidation and corrosion-resistant coatings protect turbine components from degrading due to fluids or their reaction to solid surfaces (rust)

- Abradable coatings reduce the risk of physical wear and tear when moving blades comes in contact with the turbine casing.

- Anti-fretting coatings prevent surface damage due to the contact of the slightly moving or oscillating components