Gas turbine engines operate in extreme temperatures during power generation. The cooling system is critical, protecting vital components from heat damage. Without it, these machines fail within minutes of starting up.

Allied Power Group in Houston, Texas has decades of experience in gas turbine repair and maintenance. They have manufactured and refurbished more than 1,500 parts sets, with zero failures. Each component meets strict quality standards and is fully interchangeable with OEM designs.

Modern power generation relies on reliable cooling system performance. Failures lead to costly shutdowns and equipment damage. Allied Power Group specializes in restoring damaged components with advanced repair techniques. Their services include rotor life extension and complete turbine control system upgrades.

Key Takeaways

- Gas turbine cooling systems protect engines from extreme operating temperatures

- Allied Power Group offers 65+ years of OEM manufacturing experience

- Proper turbine maintenance prevents costly equipment failures and downtime

- The company has delivered 1,500+ parts sets with zero failures

- All repaired components are 100% interchangeable with OEM designs

- Services include rotor life extension and combustion optimization

- Houston Texas facility provides extensive industrial gas turbines support

Understanding Gas Turbine Cooling Systems and Their Critical Components

Gas turbines operate at extreme temperatures, pushing materials to their limits. Modern industrial gas turbines reach inlet temperatures over 2,400°F. This necessitates sophisticated cooling systems to protect critical components. These systems employ various methods to manage heat and ensure reliable operation.

Film Cooling and Air Cooling Methods in Industrial Gas Turbines

Film cooling protects turbine blades by creating a cool air layer over component surfaces. Small holes drilled into blades release cooling air, forming a thin barrier against hot gases. This method reduces surface temperatures by up to 300°F.

Air cooling systems employ multiple approaches:

- Convection cooling through internal passages

- Impingement jets targeting specific hot spots

- Transpiration cooling through porous materials

- Heat exchanger systems for pre-cooling combustor air

Internal Cooling Passages and Hot Gas Path Components

Internal cooling channels snake through turbine blades and vanes like tiny serpentine pathways. These passages direct cooling air from the compressor through the hot gas path components. Regular maintenance prevents blockages that could cause catastrophic failures.

Key hot gas path components requiring internal cooling include first-stage nozzles, turbine blades, transition pieces, and combustor liners. Each component uses customized cooling designs based on local heat loads and stress patterns.

Role of Thermal Barrier Coatings in High Temperature Protection

TBCs act as insulation between hot gases and metal components. These ceramic coatings, typically made from yttria-stabilized zirconia, reduce metal temperatures by 200-300°F. Modern TBCs protect components throughout the hot gas path, from combustor walls to turbine airfoils.

Regular inspection identifies coating damage such as spallation or cracking before base metal exposure occurs. Proper TBC maintenance extends component life and maintains turbine efficiency.

Common Cooling System Failures in Heavy Duty Gas Turbines

Cooling systems in heavy duty gas turbines endure extreme temperatures and harsh environments. Failure in these systems can severely impact turbine performance. Regular monitoring is essential to catch issues early, preventing costly shutdowns.

Oxidation and Corrosion Issues in Turbine Blades and Nozzles

High temperatures cause oxidation on turbine blades and nozzles during operation. Metal surfaces react with oxygen, forming scales that flake off. This weakens the material and alters the blades’ aerodynamics.

Corrosion occurs when contaminants in the air or fuel create corrosive compounds. Salt from coastal environments speeds up corrosion. Fuel nozzles are severely damaged by sulfur compounds reacting with moisture.

Blockages in Cooling Air Channels and Flow Path Restrictions

Debris, dust, and oxidation products block cooling passages. These blockages reduce cooling efficiency and create hot spots. The remaining air must work harder, increasing pressure drops.

| Blockage Type | Common Locations | Impact on Performance |

|---|---|---|

| Dust and Debris | Blade cooling holes | 15-20% cooling reduction |

| Oxidation Scale | Internal passages | 25-30% flow restriction |

| Carbon Deposits | Fuel nozzle tips | Uneven flame patterns |

Degradation of Combustion Components Under Operating Temperatures

Combustion components endure the highest temperatures. Thermal barrier coatings crack and spall off with repeated heating. Metal parts deform, affecting performance. Water cooling systems accumulate mineral deposits and biological growth, reducing efficiency.

Gas Turbine Cooling System Repairs

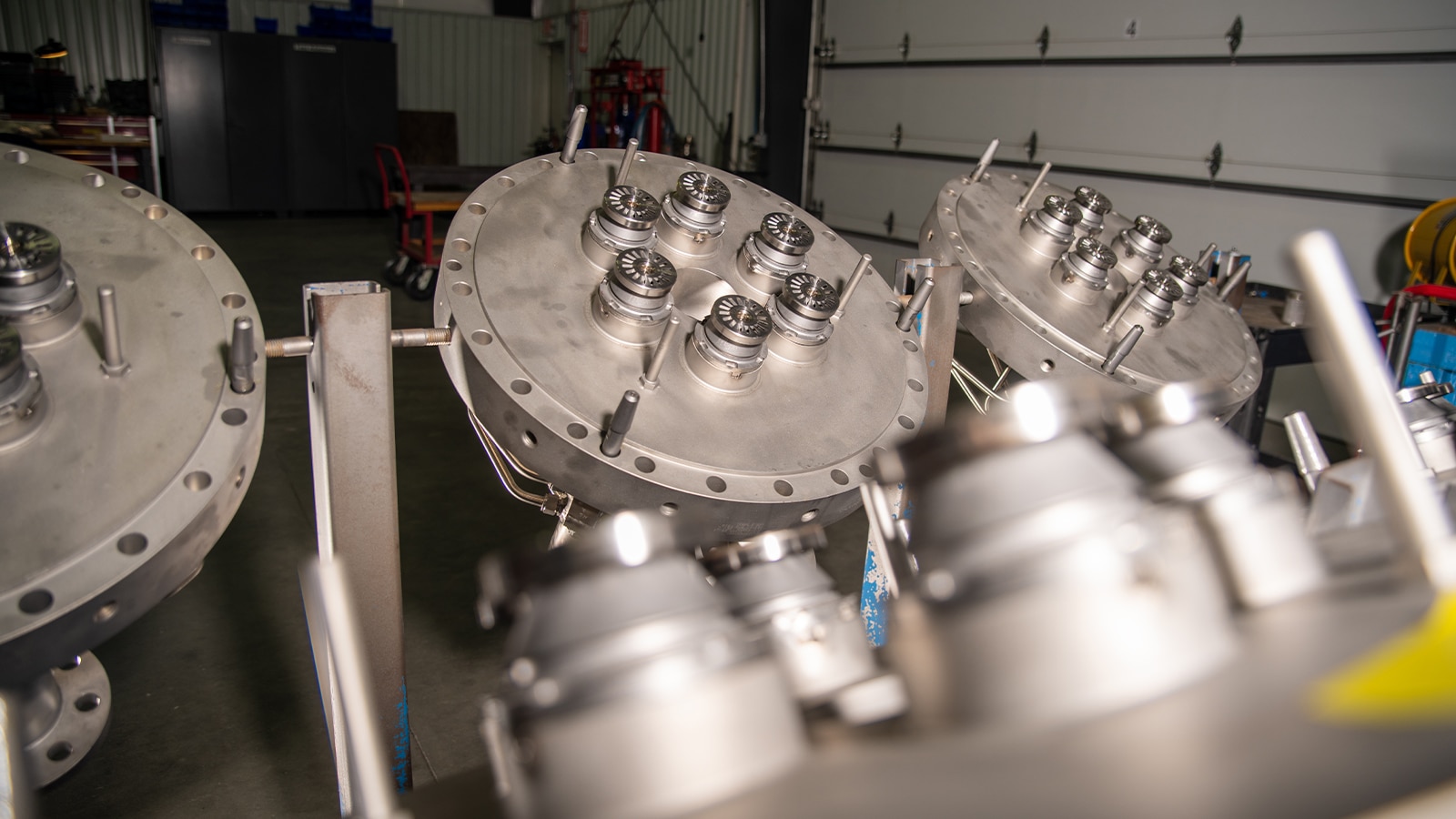

Professional gas turbine cooling repair services are essential for maintaining power plant efficiency. Allied Power Group, with over 30 years of experience, offers a wide range of services. They handle everything from routine maintenance to emergency repairs.

The repair process involves thorough inspections and cleaning. Technicians check each part for wear, damage, and cooling efficiency. Specialized machining ensures gas turbine parts meet exact specifications. Heat treatment enhances material strength post-repair.

Non-destructive testing confirms component integrity without causing harm.

Critical repair techniques include:

- Precision welding for crack repairs

- Brazing for joining dissimilar metals

- Advanced coating applications for surface protection

- Complete overhaul of cooling passages

| Turbine Model | Repair Capability | Typical Outage Duration |

|---|---|---|

| GE Frame 5 | Full regenerative repair | 14-21 days |

| GE Frame 7E/EA | Combustion section overhaul | 10-14 days |

| Siemens SGT-600 | Cooling system restoration | 7-10 days |

| Mitsubishi 501F | Blade cooling repair | 14-18 days |

Scheduled maintenance services prevent unexpected failures and extend equipment life. Expert supervisors oversee both planned and emergency repairs. The team handles complete turbine moving and installation when necessary. Every repair follows systematic procedures to ensure reliable operation after the outage ends.

Advanced Repair Techniques for Turbine Components

Modern gas turbine repair demands sophisticated methods to restore components to their peak performance. These techniques extend equipment life while maintaining efficiency standards. Advanced approaches combine cutting-edge technology with proven industrial practices. They deliver reliable solutions for power generation facilities.

Reverse Engineering and Parts Re-Engineering Services

Reverse engineering transforms damaged turbine components into operational parts through precise analysis and recreation. This process examines original designs to develop improved replacements for compressor blades, combustor sections, and turbine parts. Engineers use advanced scanning technology to capture exact dimensions and material specifications.

Parts undergo rigorous testing at temperatures reaching 1,500°C to verify performance under extreme conditions. This validation ensures replacement components match or exceed original equipment specifications for gas turbine performance.

Weld Repair and Heat Treatment Processes

Professional weld repair restores structural integrity to damaged turbine components. Certified technicians apply specialized welding techniques to mend cracks, erosion damage, and material degradation. Each repair follows strict protocols to maintain metallurgical properties.

Heat treatment processes strengthen repaired areas and relieve internal stresses. Controlled heating and cooling cycles restore material properties affected by years of operation. This optimization ensures repaired components withstand centrifugal forces and thermal cycling during service.

Rotor Life Extension and Performance Enhancement Methods

Gas turbine rotor restoration involves complete disassembly and inspection of all rotating components. Technicians examine each part for wear patterns, crack formation, and dimensional changes. Advanced diagnostics identify any signs of impending failure.

Enhancement procedures improve rotor balance and aerodynamic efficiency. Precision machining restores critical tolerances while specialized coatings protect against future degradation. These repairs extend operational life beyond manufacturer recommendations while maintaining safety standards.

Maintenance Services and Outage Management

Regular maintenance is essential for gas turbines to operate efficiently. It ensures the cooling, control systems, and critical components function optimally. This directly affects the turbines’ performance and power output.

Effective outage management is a complex task. Technicians meticulously inspect every part, from the turbine inlet to the generator. They verify valve operations, compressor functionality, and coolant system performance. These checks prevent unexpected failures and ensure consistent operation.

- Monitoring coolant flow rates and temperatures throughout the system

- Cleaning and inspecting inlet air cooling components

- Testing valve response times and calibrating control systems

- Checking compressor blade condition and clearances

- Verifying generator alignment and electrical connections

Modern maintenance employs advanced diagnostic tools to catch issues early. Thermal imaging spots hot spots, indicating cooling problems. Ultrasonic testing uncovers internal cracks before they lead to failures. These technologies ensure optimal performance and lower repair costs.

| Maintenance Activity | Frequency | Impact on Performance |

|---|---|---|

| Coolant System Inspection | Monthly | Prevents 15% efficiency loss |

| Control Systems Calibration | Quarterly | Maintains stable power output |

| Inlet Air Cooling Service | Semi-annually | Increases output by 10-20% |

| Valve Testing | During outages | Ensures safe operation |

Water treatment programs safeguard cooling systems from scale and corrosion. Special chemicals maintain coolant cleanliness, preventing blockages. This care extends equipment life and preserves gas turbine performance at design levels.

Why Choose Allied Power Group for Your Turbine System Repairs

Allied Power Group excels in the gas turbine services sector, boasting decades of OEM expertise. They provide dependable repair solutions, ensuring power plants operate at maximum efficiency. Their technical teams are adept at handling the specific needs of industrial turbines, crafting tailored repair plans for each client.

Extensive Experience Across GE Frame Models

Allied Power Group is a leading name in servicing GE heavy-duty turbines, with a proven track record in OEM capabilities. Their expertise covers a wide range of models:

- Frame 5 gas turbines

- 6B and 7B series

- 7E/EA configurations

- 7F advanced systems

- Frame 9 large-scale units

This broad knowledge of GE turbines ensures precise diagnostics and effective repairs for any configuration in your power generation facility.

Westinghouse and Siemens Turbine Service Capabilities

Allied Power Group also boasts extensive experience with Westinghouse and Siemens gas turbines. Their technicians handle W251/TG20, W501, W101/TG7, and 701D/TG50 models with the same meticulous care as an OEM.

Long-Term Service Agreements and Supply Chain Management

Allied Power Group offers flexible long-term service agreements to cut lifecycle costs. These contracts include supply chain optimization, ensuring timely availability of critical parts. Their extensive OEM gas turbine product inventory and modification capabilities help facilities maintain consistent power output while effectively managing maintenance budgets.

Conclusion

Repairing gas turbine cooling systems requires deep understanding of advanced cooling technologies and maintenance practices. These systems are critical in power generation and aircraft engines, ensuring turbines operate reliably under harsh conditions. Managing temperatures up to 1300 °C demands precise control over flow rates and air temperature within the gas turbine system.

Each cooling method is essential for safeguarding components against mechanical and thermal damage. Refrigeration, evaporative cooling, and TIAC installations at the air intake are key for power augmentation. Knowing the schematic of each system is vital for technicians to spot issues like cavitation and perform repairs as per OEM guidelines.

The efficiency of gas turbines heavily relies on the upkeep of their cooling systems. Whether it’s for gas and steam turbines in combined cycle plants or industrial units, Allied Power Group offers thorough repair solutions. Their expertise ranges from routine maintenance to complex repairs, ensuring your equipment runs safely and efficiently for extended periods.

FAQ

What are the main types of cooling methods used in gas turbine systems?

Gas turbines employ various cooling techniques. Film cooling forms a protective air layer over components. Internal air cooling directs air through component passages. Steam injection and evaporative cooling with water spray systems also play roles. Thermal barrier coatings (TBCs) further reduce heat transfer.

How often should gas turbine cooling systems undergo maintenance and inspection?

Maintenance schedules vary based on operating conditions and manufacturer guidelines. Regular checks include monitoring coolant flow and inspecting cooling channels. It’s also vital to examine turbine blades and TBC integrity. Allied Power Group advises following OEM recommendations and offers both scheduled and unscheduled services.

What are the most common failures in industrial gas turbine cooling systems?

Failures often stem from blockages in cooling channels due to debris or oxidation. Erosion of cooling holes and steam injection nozzles is another issue. Corrosion and scaling in water systems and TBC spallation under high temperatures are also common. Seal and gasket leakage in the hot gas path is a frequent problem.

Which GE gas turbine models does Allied Power Group service?

Allied Power Group services a wide range of GE heavy-duty gas turbines. This includes Frame 5, 6B, 7B, 7E/EA, 7F, and 9 models. They also work on Westinghouse/Fiat models and Siemens gas turbines.

What repair techniques are used for turbine blade and nozzle restoration?

Advanced repair methods include welding, brazing, machining, heat treatment, and coating. Allied Power Group employs reverse engineering for part re-engineering. They also conduct non-destructive testing and apply specialized cleaning and performance enhancement procedures.

How does inlet air cooling improve gas turbine performance and power output?

Inlet air cooling systems, like evaporative cooling, lower air temperature before it enters the compressor. This increase in air density boosts combustion efficiency and power output. It’s critical during high temperatures when turbine performance usually drops.

What is included in a complete gas turbine rotor repair service?

Rotor repair involves a full restoration process. This includes disassembly, inspection, diagnosis, cleaning, and calibration. Allied Power Group’s rotor life extension program uses life assessment to predict material failure and replace parts beyond OEM recommendations.

How do thermal barrier coatings protect turbine components in the combustor?

TBCs act as a thermal insulation layer, shielding metal components from extreme temperatures. This reduces mechanical stresses and prevents oxidation. Regular inspections and repairs are necessary due to spallation or adhesion issues at high temperatures.

What are the benefits of long-term service agreements (LTSA) for gas turbine maintenance?

LTSAs offer extensive maintenance coverage, reducing lifecycle costs and ensuring consistent performance. They guarantee parts availability and include scheduled maintenance. Allied Power Group, with 65+ years of OEM experience and 1500+ sets of parts in operation, provides these agreements.

How can combustion optimization improve gas turbine system efficiency?

Combustion optimization involves autotuning control systems and upgrading fuel nozzles. It also includes modifying combustion components for optimal flow and temperature. This enhances efficiency, reduces emissions, and extends component life by maintaining proper operating conditions.