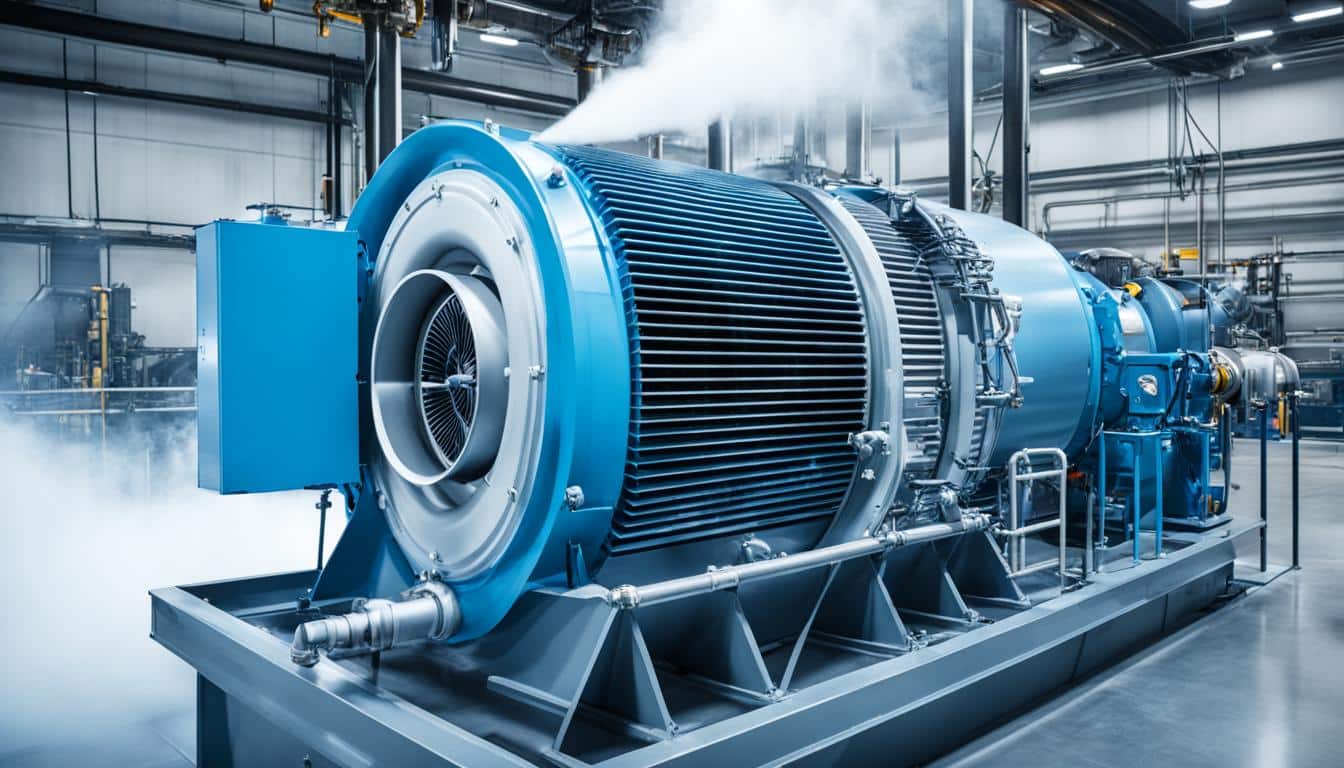

The relentless pursuit of enhanced power generation efficiency has led the industry to focus on optimizing industrial turbine cooling performance. As a substantial determinant of operational integrity and efficiency, the role of turbine cooling optimization has never been more pivotal. To catapult the potential of these industrial giants, cutting-edge industrial turbine cooling techniques are consistently being refined.

Improving turbine cooling efficiency is not just about ramping up power output; it’s also about elevating the overall health of the machinery. Enhancing turbine cooling performance translates directly to extended turbine lifespan and reduced maintenance costs. Adherence to turbine cooling best practices and the implementation of advanced strategies for optimizing turbine cooling are essential for achieving peak performance in the volatile sphere of power generation.

In this context, impactful innovations and the precise application of technologies are central to driving progress. Let’s take a closer look at how these advancements are significantly changing the face of industrial turbine operations.

Key Takeaways

- Significance of advanced cooling in improving industrial turbine efficiency.

- Role of digital controls and tailored approaches in turbine cooling optimization.

- Importance of continuous innovation in industrial turbine cooling techniques.

- Impact of improving turbine cooling efficiency on operational costs and maintenance.

- Benefits of adopting turbine cooling best practices for sustainable power generation.

- Strategic necessity for strategies for optimizing turbine cooling in modern power plants.

Advancements in Cooling System Design for Gas Turbines

The quest for thermal efficiency in gas turbines has prompted innovative strides in turbine blade design. Central to this pursuit is the advancement of internal cooling techniques which safeguard the functional integrity of gas turbine blades during high-temperature operations. In engineering state-of-the-art cooling solutions, the inclusion of cooling passages in turbine blades has become pivotal. These passages are crucial for distributing cooling air throughout the blades, thereby maintaining optimal metal temperatures and ensuring prolonged durability.

Integrating methods of computational fluid dynamics (CFD) and conjugate heat transfer analysis, designers are adeptly performing computational optimization to simulate and enhance cooling systems. This ensures the achievement of an optimal cooling configuration that is meticulously tailored to each blade’s unique thermal load profile. The use of numerical optimization techniques permits analysts to iteratively refine the design, improving the flow and thermal conditions facilitated by the strategically placed cooling passages.

The evolutionary curve in the design and optimization of gas turbine blades is steepening, with convergence upon solutions that meld efficiency with resilience. Here are some of the key features and benefits derived from the latest advancements in turbine blade cooling systems:

- Extended component lifespan due to reduced high temperature thermal stresses

- Enhanced overall engine performance from improved thermal management

- Optimized usage of cooling air, leading to efficiency gains in heat transfer performance

| Cooling Technique | Benefit | Technological Application |

|---|---|---|

| Convection Cooling | Uniform Temperature Distribution | Advanced Cooling Passages Design |

| Film Cooling | Thermal Barrier Protection | Micro-perforated Surface |

| Impingement Cooling | Enhanced Heat Transfer | Jet Arrays Targeting Hot Spots |

By mastering the interplay between cooling air distribution and turbine blade material constraints, the design of robust yet efficient internal cooling systems becomes a transformative component in gas turbine technology.

The relentless design and optimization process for internal cooling systems has led to more predictable and controllable outcomes, allowing operational parameters to be pushed further without compromising the longevity or safety of the gas turbine blades. Achieving an equilibrium between high performance and reliability reflects the symbiotic relationship between physics-driven computational optimization and pragmatic engineering applications.

Future developments in cooling technology will likely hinge on the progressive application of numerical optimization, pushing the boundaries of what is possible in gas turbine blade performance. The triumph of these cooling strategies lies in their contribution to increasing the overall thermal efficiency of gas turbines, thereby bolstering the power generation sector with cleaner and more economical energy production.

Collaborative Problem Solving for Turbine Cooling Optimization

In the realm of power generation, turbine cooling system optimization is crucial for enhancing the overall performance of the engine. This invigorates the need for continually evolving practices that fine-tune operational efficiency to match the specific dynamics of each facility. Within this scope, Mitsubishi Power leads the charge in delivering tailor-made options that accommodate the varied operating conditions and design intricacies of different plants.

Custom Solutions for Each Power Plant

Recognizing the diversity of power plant configurations, effective turbine cooling enhancements demand an individualized approach. As such, solutions must factor in the distinct characteristics of turbine vanes and turbine components, ensuring that metal temperature regulation and gas turbine blade cooling are addressed with precision. This bespoke form of problem-solving involves sophisticated optimization algorithms, paving the way for sustained operational efficiency.

Implementing Adjustable-Speed Fans for Operational Efficiency

The challenge of overcooling, which impactfully deters efficiency, is met with innovation through the utilization of adjustable-speed fans. This transformative move revamps traditional cooling methodologies, instating a more dynamic and responsive system that markedly adjusts to real-time demands, thus maintaining an optimal cooling pace and directly influencing gas turbine efficiency.

Frequently Asked Questions

What are the key strategies for optimizing industrial turbine cooling performance?

Key strategies include using advanced computational optimization techniques to design cooling passages in turbine blades, implementing digital control systems for precise temperature management, and customizing cooling solutions for specific power plants’ operating conditions.

How do design optimizations in turbine blades affect internal cooling?

Design optimizations in turbine blades, achieved through computational and numerical optimization, enhance internal cooling by creating more efficient cooling passages. This leads to a more uniform temperature distribution within the blade, thus improving thermal efficiency and longevity of the blades.

What benefits do adjustable-speed fans provide in turbine cooling optimization?

Adjustable-speed fans offer the ability to precisely control the amount of cooling air delivered to the turbine, thus improving operational efficiency by preventing overcooling and better matching the cooling requirements to the engine’s operating conditions.

Why is it important to customize cooling solutions for each power plant?

Customizing cooling solutions is important because each power plant has unique design features and operating conditions that affect the performance of their turbine cooling systems. Tailored solutions ensure that the cooling system is optimized for maximum efficiency and reliability, reflecting the specific needs of the plant.