In the realm of energy production, gas turbine engines stand as paragons of innovation and efficiency. Central to their operational excellence is the gas turbine lubrication system, a sophisticated network designed to minimize friction and wear, thereby ensuring longevity and reliability. Not unlike their counterparts in piston engines or steam turbines, these lubrication systems for gas turbines are intricately engineered to deliver lubricant across critical surfaces, preventing damage and dissipating the intense heat generated during high-speed operations.

The dynamic performance of these systems pivots on the quality of the turbine lubrication oil. This quintessential fluid must finely balance low viscosity for smooth flow and high viscosity to endure the substantial pressures characteristic of gas turbines. With configurations like dry-sump and wet-sump setups, the architecture of gas turbine lubrication systems aligns with specialized applications, underscoring the critical role these systems play in the competitive landscape of turbine efficiency.

Key Takeaways

- Gas turbine lubrication systems are essential for reducing friction and managing heat within the engine.

- Lubrication oil must be formulated to handle a broad range of temperatures and pressures.

- Dry-sump and wet-sump systems each offer distinct advantages, guiding the design choices for different gas turbine applications.

- Maintaining optimal viscosity levels is crucial for the performance and longevity of gas turbine lubrication systems.

- Modern gas turbines utilize advanced features like pressure relief systems to maintain steady operational conditions.

The Critical Role of Lubrication in Gas Turbine Operations

The prowess of a gas turbine engine is significantly enhanced by its lubrication system, designed to ensure peak performance under extreme operational conditions. The lubricant, serving as the lifeblood for the gas turbine, multi-tasks in protecting bearings, managing heat, and facilitating various mechanical functions.

Essential Functions of Gas Turbine Lubrication Systems

Gas turbine lubrication systems, beyond minimizing friction, play a pivotal role in maintaining the integrity and efficiency of the engine’s overall mechanism. The bearings depend heavily on the lubrication provided to ensure seamless functioning and stability. The oil system extends the gas turbine’s lifespan by cooling these bearings and lubricating other critical components. Our rundown of a turbine’s lubrication circuit encompasses reservoirs, pumps, filters, and heat exchangers, all collaborating to maintain the intricate balance vital for turbine operations.

Comparing Wet-Sump and Dry-Sump Lubrication Methods

The choice between wet-sump and dry-sump lubrication methods can have a profound impact on the operation and performance of gas turbines. While the aviation gas turbine engines commonly employ wet-sump systems for their lightweight, compact design, aeroderivative gas turbines are often paired with dry sump lubrication systems due to their higher oil capacity and superior cooling efficiency. Making an informed decision on the lubrication method is therefore a critical step in aligning with both engineering standards and operational expectations.

| Feature | Wet-Sump Systems | Dry-Sump Systems |

|---|---|---|

| Oil Storage | Internal | External |

| Weight/Design | Lightweight/Compact | Heavier/Larger |

| Cooling Efficiency | Lower due to engine proximity | Higher with enhanced oil capacity |

| Maintenance Frequency | Higher due to temperature stress | Lower with better temperature management |

Lubricant Viscosity and Its Impact on Turbine Performance

Viscosity is one of the most critical factors in lubricant selection for gas turbine engines. The operational temperature range within which the turbine functions demands a lubricant that can maintain its performance characteristics without degradation. Synthetic oils, with their tailored formulations, cater to this need by providing resistance to shear forces between components under high pressure, ensuring a film that fulfills both lubricating and cooling requirements—thereby preserving the delicate balance essential for the gas turbine’s operational harmony.

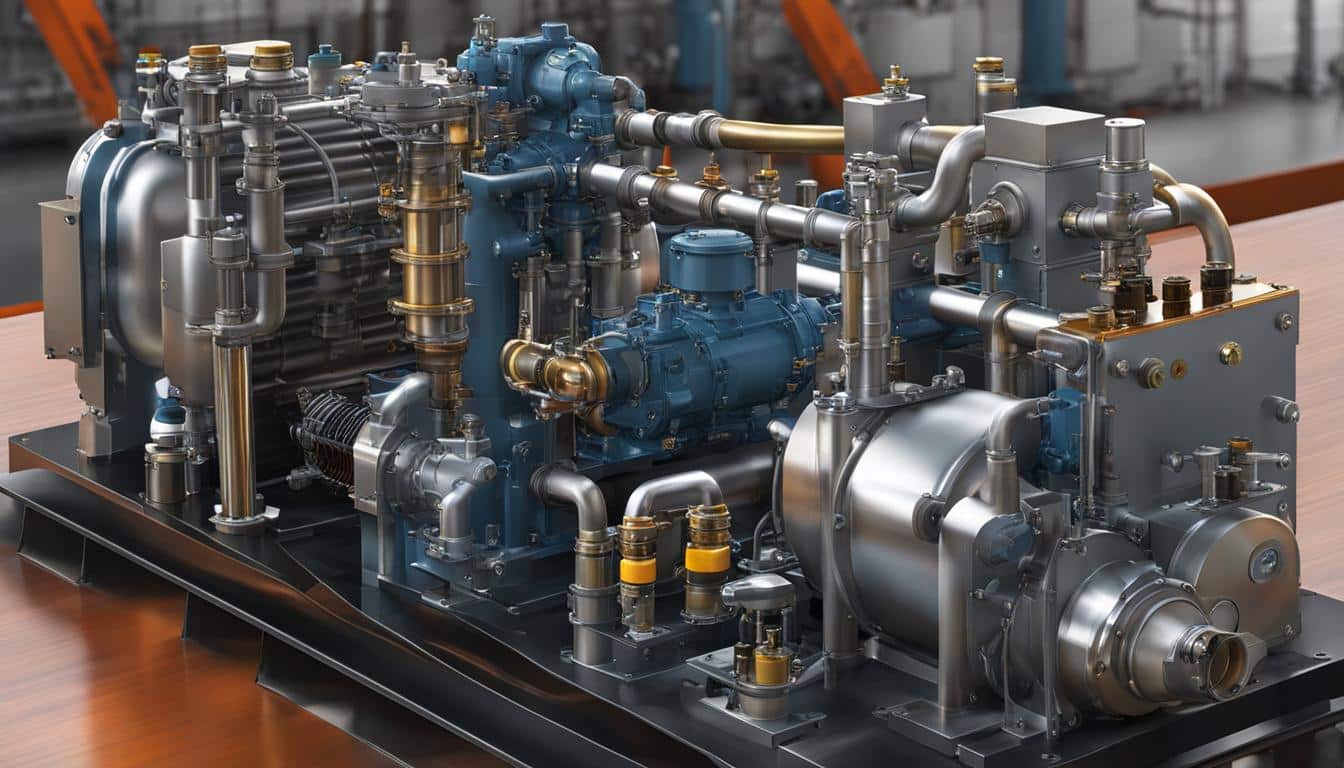

Components of Gas Turbine Lubrication Systems

Gas turbine lubrication systems are sophisticated assemblies crucial for maintaining the continuous and reliable operation of turbine machinery. At the heart of these systems lies a network of bearings and oil system components, calibrated to work seamlessly within a regulated pressure environment to ensure the integrity of the turbine’s operations.

Bearings: The Heart of the Lubrication Process

The stability and efficiency of gas turbines are largely dependent on the high-performance turbine bearings and journal bearings that facilitate the smooth rotation of the machinery’s shafts. These fluid film journal bearings are essential, actively working to lubricate the rotating shaft and maintain the balance of the entire rotor-bearing system. Their careful design is paramount to coping with the high rotational speeds and thermal stresses encountered during operation.

Understanding Oil Systems in Turbine Engines

The comprehensive oil system within a turbine engine works diligently to ensure each moving part is sufficiently lubricated and cooled. Beginning with the oil tank, the oil pump initiates the oil flow, propelling it through various components such as the oil cooler, oil heat exchanger, and oil filter. The robust system incorporates a range of pumps including the main lube pump, auxiliary lube pump, and emergency lube pump to support different phases of turbine operation.

Pressure Relief Systems and Maintaining Constant Pressure

A pivotal feature within the lubrication system is the pressure relief mechanism, which manages system pressure fluctuations due to variable engine speeds. As pressure varies with engine demands, the pressure relief valve and pressure switches act to maintain constant pressure, ensuring both the optimal lubrication of components and regulation of oil temperature within the turbine system, safeguarding it against performance-impeding stress.

This intricate interplay between system components is showcased by mapping out the complete journey of engine’s oil from the tank to the critical high-speed mechanical parts. Understanding the nuanced roles of each component emphasizes their collective responsibility to uphold the turbine engine’s functionality and efficiency.

| Component | Function | Role in Lubrication System |

|---|---|---|

| Turbine Engine Oil | Lubricate & Cool | Facilitates smooth operations across varying temperature ranges |

| Oil Pump | Pressurize & Circulate | Propels oil throughout the system, maintaining consistent flow |

| Oil Cooler/Heat Exchanger | Temperature Regulation | Reduces oil temperature to optimal operating levels |

| Pressure Relief Valve | Pressure Control | Modulates oil pressure, guarding against extremes |

| Pressure Switches | Monitoring & Adjustment | Real-time system pressure tracking to secure operational stability |

Each element within the gas turbine lubrication array is fine-tuned to synergistically mitigate the myriad of physical and mechanical challenges presented during the turbine’s operation, illustrating the complex dance of dynamic pressure, flow, and temperature controls instrumental for optimal turbine performance.

Conclusion

As the dynamics of energy transformation and propulsion advance, the quintessence of peak performance in gas turbines remains inexorably tied to their lubrication systems. Integral to this are the precision-engineered system components, which operate in concert to mitigate wear and maintain stability under extreme conditions. It is the harmonious interplay of these components that fosters the high efficiency and reliability demanded by the industrial sectors. The distinguishing features of gas turbine engine lubrication – choosing the right sump system, ensuring optimal lubricant viscosity, and executing consistent pressure management – are not merely details in the design but pivotal factors that underscore longevity and optimal performance.

In summary, the collective attributes of gas turbine lubrication systems hinge on a deep understanding of mechanical and fluid principles, driving the turbines to operate with impeccable fluidity and grace. Such a synergy of design and technology not only ensures the seamless operation of turbines but also potentiates the engines to meet the demands of a world that steadily propels towards greater heights of energy efficiency and reliability. As turbines continue to evolve, so too will the sophistication of their lubrication systems, maintaining their pivotal role in the infrastructure of tomorrow’s energy and transportation systems.

Frequently Asked Questions

What are the key functions of gas turbine lubrication systems?

Gas turbine lubrication systems serve multiple critical functions including reducing friction between moving parts, supporting bearings for rotor stability, cooling components to dissipate heat, providing oil to the fuel system, and acting as hydraulic fluid for starting mechanisms.

How do wet-sump and dry-sump lubrication methods in gas turbines differ?

Wet-sump systems store lubrication oil within the engine and are typically found in aviation gas turbine engines. Dry-sump systems have an external oil storage tank and are common in aeroderivative gas turbines, allowing for larger oil capacity and improved cooling capabilities.

Why is lubricant viscosity important for gas turbine performance?

The viscosity of the lubricant is crucial because it needs to be fluid enough to circulate through the engine while being viscous enough to form a protective film between parts under high pressure. It ensures the reliability of the system and helps regulate temperature across varying operational conditions.

What roles do bearings play in gas turbine lubrication?

Bearings, especially journal bearings, are central to gas turbine lubrication, ensuring the stability and alignment of high-speed rotating shafts. They must receive precise lubrication to function efficiently and prevent leakage or excess wear.

What components make up a gas turbine’s oil system?

The gas turbine oil system includes components such as the reservoir or tank, oil pumps (main, auxiliary, emergency), oil coolers, heat exchangers, filters, pressure relief valves, and pressure switches. These parts collectively maintain a steady flow and temperature of the oil across the system.

How do pressure relief systems in gas turbines maintain constant pressure?

Pressure relief systems in gas turbines utilize pressure relief valves to regulate oil pressure within the system. This ensures consistent lubrication and cooling, regardless of changes in engine speed, safeguarding the engine against pressure-related issues.