Power plants depend on gas and steam turbines to produce electricity efficiently and safely. Failures in these systems, often due to incorrect materials, can have devastating consequences. Positive material identification (PMI) acts as a vital defense against such failures.

PMI testing employs cutting-edge technology to confirm the chemical composition of metals without causing harm. This verification process is now a cornerstone in modern power generation facilities. The Electric Power Research Institute reports that nearly 10% of corrosion failures stem from using the wrong materials in critical systems.

Many power companies now mandate PMI analysis for their turbine equipment during both construction and maintenance.

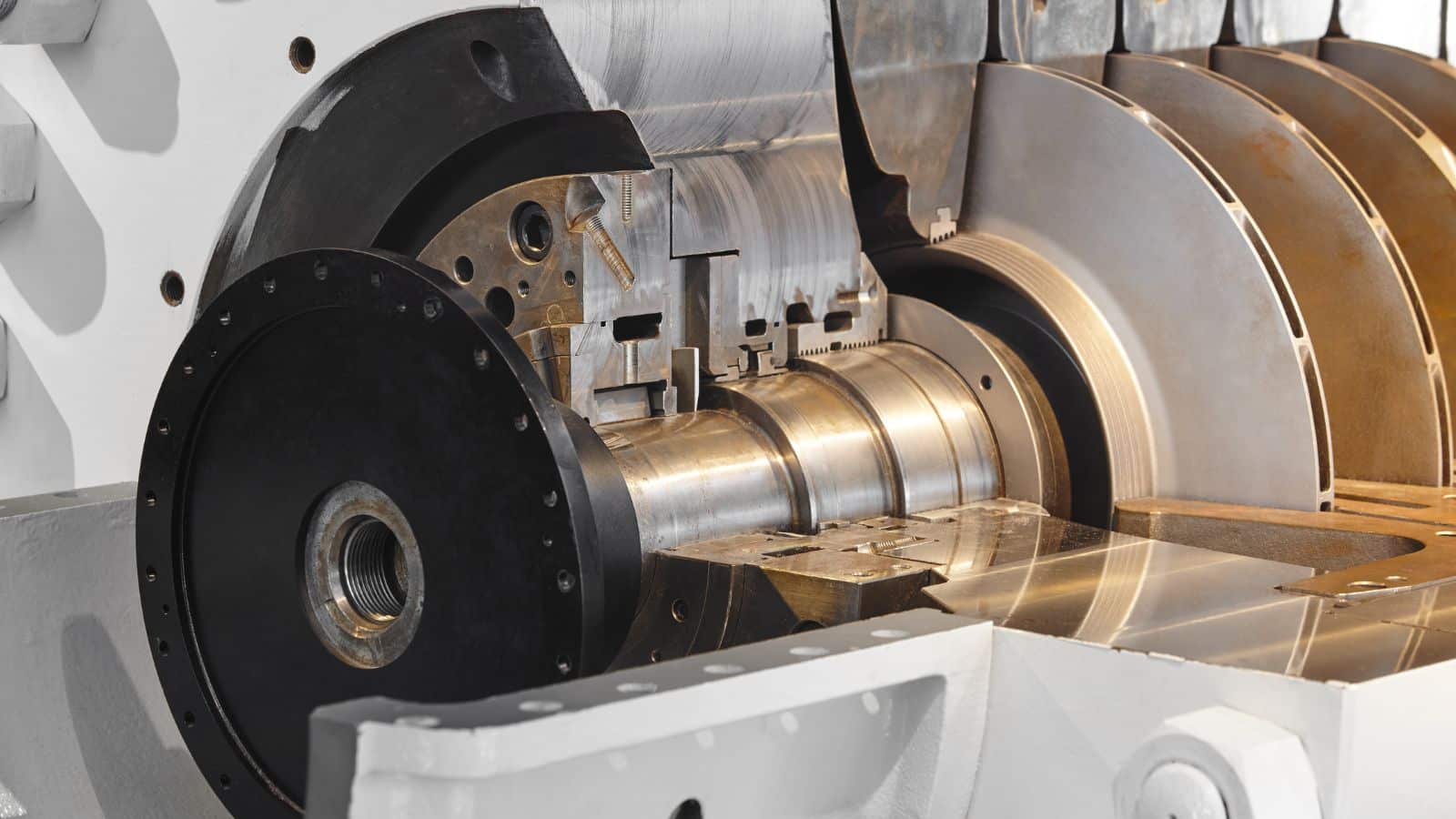

At Allied Power Group in Houston, this testing can be offered as a standalone service or as part of broader inspection programs. How to Use PMI Testing for Gas and Steam Turbine Components involves verifying material composition in critical parts like blades and rotors, confirming replacement components meet specifications, and identifying degradation to prevent failures and extend equipment life.

Key Takeaways

- PMI provides accurate chemical analysis of turbine materials without causing damage

- About 10% of corrosion accidents result from using wrong materials in critical systems

- Positive material identification works for both gas turbine and steam turbine applications

- Material verification can be done as standalone testing or part of complete inspections

- Generator components require regular PMI checks to maintain safe operations

- Modern PMI equipment delivers results quickly at the turbine location

Understanding Positive Material Identification and Its Role in Turbine Inspection

Positive Material Identification is a vital inspection technique in power generation facilities. It ensures turbine components meet exact specifications for safe and efficient operations and catastrophic operation. By analyzing the chemical composition of metals, PMI testing confirms materials identification in turbines, generators, and related equipment.

What Is PMI and Why It Matters for Power Generation

PMI is a non-destructive testing method that determines the chemical analysis of metals and alloys. Power generation plants rely on this inspection process to verify materials match their required specifications. Turbine components face extreme temperatures and pressures during operation. Using the wrong alloy can lead to catastrophic failures, unplanned outages, and safety hazards.

PMI testing helps operators verify materials when certificates are missing or when documentation appears questionable. This inspection method provides real-time results, allowing technicians to confirm material grades before installation or during turbine maintenance activities.

The Science Behind Material Verification Through Chemical Analysis

PMI equipment uses X-ray fluorescence or optical emission spectroscopy to analyze the chemical composition of metals. These instruments emit energy that excites atoms in the material being tested. The atoms then release characteristic wavelengths that identify specific key elements present in the alloy. Advanced analyzers can detect element percentages within seconds.

Key Elements Detected in Turbine Generator Components

Turbine materials contain specific key elements that determine their performance characteristics:

| Element | Symbol | Common Range (%) | Impact on Properties |

|---|---|---|---|

| Chromium | Cr | 12-25 | Corrosion resistance |

| Molybdenum | Mo | 0.5-7 | High-temperature strength |

| Nickel | Ni | 8-35 | Ductility and toughness |

| Titanium | Ti | 0.1-1 | Stabilization |

| Niobium | Nb | 0.1-1 | Creep resistance |

How to Use PMI Testing on Gas and Steam Turbine Components

Testing turbine components demands meticulous planning and execution for safety and reliability. PMI confirms each part’s adherence to exact specifications, critical for pressure vessels, piping systems, and welded joints under extreme conditions.

Essential Steps for Performing PMI on Turbine Materials

The PMI process starts with setting up and calibrating the equipment. Technicians then clean the surface to remove contaminants that could skew readings. The testing sequence is systematic, covering all critical parts. Each point is documented with its location and chemical composition results.

Identifying Critical Components and Welds with PMI

PMI testing targets areas most susceptible to failure, such as flanges, nozzles, and tube connections. Regular testing is essential to ensure the integrity of critical turbine sections during operation.

| Component Type | Testing Frequency | Risk Level |

|---|---|---|

| Pressure Vessels | 100% verification | High |

| Welded Joints | Every joint | Critical |

| Flanges | All connections | Medium |

| Internal Linings | Sample testing | Low |

Best Practices for On-Site Material Verification

Teams can conduct PMI on-site with portable analyzers for immediate results. This approach saves time and reduces costs over laboratory analysis. Color-coded systems track tested components, ensuring only correct materials are used.

X-Ray Fluorescence Technology for Alloy Grade Verification

X-ray fluorescence is the top choice for quick material identification in turbine parts. It lets engineers check alloy grade and composition in seconds, which is key for maintaining quality and safety in power plants.

XRF works by shooting x-rays at metal surfaces. Each element gives off unique energy signals when hit by x-rays. The handheld analyzer catches these signals and turns them into detailed chemical data. This method needs no prep work and doesn’t harm the part.

Today’s handheld x-ray fluorescence tools are great for checking turbine material grades and compositions. They can measure elements from magnesium to uranium. They quickly spot important alloying elements:

| XRF Analysis Capability | Performance Range | Typical Application |

|---|---|---|

| Detection Speed | 2-10 seconds | Quick alloy grade screening |

| Element Range | Mg (12) to U (92) | Full composition analysis |

| Accuracy Level | 0.01-0.5% | Verification of specifications |

| Sample Penetration | 10-50 micrometers | Surface layer examination |

The portability of xrf tools lets technicians check parts right where they are. No need to take parts out or send samples to labs. The device shows the grade and composition data right away, along with alloy designations from big libraries.

Chemical Composition Analysis of Metals and Alloys in Turbines

Turbine components need precise chemical makeup to operate safely and reliably. The exact composition of metals and alloys affects their properties, like corrosion resistance and mechanical strength. Accurate analysis is key for engineers to choose the right materials for various conditions and temperatures.

Understanding Material Properties Such as Corrosion Resistance

Corrosion resistance depends on the exact percentages of elements in alloys. For example, stainless steel grades like 316L have specific chromium and nickel levels to fight oxidation. Even small changes in chemical makeup can greatly impact turbine performance in high-temperature settings.

Verifying the Chemical Composition of Pressure Containing Parts

Pressure containing parts must undergo strict material verification to avoid failures. These include vessels, piping, heat exchangers, and reactor drums.

| Component Type | Common Alloys Used | Critical Elements |

|---|---|---|

| Piping Systems | 316L Stainless Steel | Chromium 16-18%, Nickel 10-14% |

| Heat Exchangers | Inconel 625 | Nickel 58%, Chromium 20-23% |

| Reactor Vessels | 2.25Cr-1Mo Steel | Chromium 2.25%, Molybdenum 1% |

| Fired Heater Coils | 9Cr-1Mo Steel | Chromium 9%, Molybdenum 1% |

PMI Test Method for Analysis of Stainless Steel and Alloy Components

The PMI method is a vital quality control tool for checking stainless steel and alloy components in turbine systems. It ensures materials adhere to precise specifications before installation or during routine checks.

ASTM Standards for X-Ray Emission Spectrometric Analysis

Industry experts adhere to specific ASTM standards for x-ray emission spectrometric analysis. ASTM E572 outlines guidelines for analyzing stainless and alloy steels via X-ray fluorescence spectrometry. ASTM E322 covers stainless steel variants and cast irons. These standards guarantee consistent results across different testing facilities.

These standards guarantee consistent results across different testing facilities. Technicians can accurately identify molybdenum content in Type 316 and 316L stainless steel using chemical reagents as a supplementary verification step.

Handheld X-Ray Fluorescence Equipment and Portability Benefits

The portability of the hand-held equipment has transformed field inspection capabilities. Devices like the Texas Nuclear 9266 and META scope offer direct readings of alloy grades and compositions in seconds.

Key advantages include:

- Instant results without sample preparation

- Non-destructive testing preserves component integrity

- Cost-effective screening of multiple alloy components

- Battery-powered operation for remote locations

Quality Control and Safety Compliance in Oil and Gas Industries

PMI testing is essential for quality control in sectors like oil and gas. Studies indicate that about 10% of corrosion-related accidents in oil and gas operations stem from using materials with inadequate chemical composition.

Different sectors have varying quality control standards. Each industry has its own rules for material verification, from oil and gas facilities requiring verification of all pressure-containing components to power generation plants mandating testing of turbine alloys.

Implementing quality control procedures correctly ensures the right alloy materials are used where needed. Once verified, components receive an AV low stress stamp marking. This permanent mark helps maintenance teams track material compliance throughout the equipment’s life.

The fabrication phase is a critical point for material verification. Components are tested before installation to avoid costly retrofitting or safety hazards. Oil and gas refineries, among others, have adopted detailed testing protocols. These protocols include PMI analysis as part of their standard quality control workflows. This approach greatly reduces the risk of material mix-ups during construction and maintenance.

Pre-Service and In-Service Inspection of Critical Components

Turbine components need thorough inspection throughout their life. Pre-service and in-service checks ensure critical parts and welds adhere to safety and performance standards.

Inspection and Test Plan Requirements

An inspection and test plan is essential for verifying material quality. New and existing alloy piping systems must undergo PMI testing, following API 578 guidelines. The plan details specific inspection points, sampling frequencies, and testing methods for each component type.

Third Party Inspection Agency Protocols

A third party inspection agency provides independent verification of PMI results. These agencies adhere to strict protocols for unbiased material assessment. Acceptance criteria outline minimum standards for material composition, with equipment tolerance allowing ±0.5% variation for major alloying elements.

PMI Report Documentation

A PMI report provides detailed data on each tested component. Test reports adhere to international standards like DIN 50049 or BS/EN 10204 type 3.1C certification. The report includes item numbers, material specifications, mill certification references, and chemical compositions.

Asset Integrity Management Across Many Industries

Asset integrity management is critical across various sectors, ensuring safe and efficient operations. Industries use PMI testing to prevent failures and meet safety standards.

Testing on the production floor adheres to strict protocols. Random sampling involves examining at least three points per pipe length. If tests show unacceptable materials, the entire batch is scrutinized.

Piping Systems and Pressure Vessels PMI Examination

PMI examination for piping systems and pressure vessels is critical for ensuring material quality in industrial equipment. It verifies that piping components meet exact specifications before and during use.

| Component Type | Testing Frequency | Minimum Test Points |

|---|---|---|

| Pipes and Fittings | Random per heat | 3 points per length |

| Flanges and Valves | Each component | 1 point minimum |

| Finished Groove Welds | 5% random basis | Inside and outside |

| Pressure Vessels | All critical welds | Multiple locations |

Allied Power Group in Houston: Implementation of PMI Testing Method

At Allied Power Group in Houston, we lead in turbine component inspection with advanced PMI testing. This method is a key quality control step in our manufacturing, ensuring components are reliable and preventing failures in power systems.

After fabrication, every welded joint and component is inspected thoroughly. The company uses PMI and hydrostatic tests together. Our staff are trained to use Texas Nuclear 9266 and META scope spectrometers for efficient on-site testing.

Conclusion

PMI test procedures are vital in material testing for gas and steam turbine facilities. API standards guide technicians to check carbon steel and alloy elements in every critical part. Regular PMI testing prevents nearly 10% of corrosion-related failures, which could shut down turbine operations.

The success of any turbine operation depends on knowing the exact material grade of every pipe and component. PMI testing provides this critical information before problems develop. By identifying the right metal composition in each weld and connection, facilities can plan maintenance schedules that prevent unexpected failures and extend equipment life.

FAQ

What is PMI testing and why is it essential for turbine generator components?

PMI, or Positive Material Identification, is a non-destructive method for checking metals and alloys’ chemical makeup. It’s vital for turbine generator parts because about 10% of corrosion accidents are due to wrong material composition.

Which elements can PMI detect in steam turbine and gas turbine materials?

PMI can spot key elements like chromium (Cr), molybdenum (Mo), nickel (Ni), titanium (Ti), and niobium (Nb) in alloy steels and stainless steels. It also checks carbon content in specific grades and identifies nickel alloys, copper nickel alloys, aluminum-bronze, and titanium.

How does X-ray fluorescence (XRF) work for material identification?

XRF uses x-ray flux to expose materials. The materials reflect this radiation, creating unique energy levels for each element. The device measures these intensities and energies for both qualitative and quantitative analysis.

What are the acceptance criteria for PMI examination in piping systems?

For piping systems, PMI must detect alloy elements as specified in chemical composition within certain ranges. Reports follow DIN 50049 or BS/EN 10204 type 3.1C or 3.2 standards.

When should PMI be performed during fabrication and installation?

PMI testing is essential after completion of fabrication, with 100% verification for parts. For piping bulk materials, examination is random per heat with a minimum of 3 points per pipe length.

What types of pressure vessels and components require PMI examination?

PMI is required for pressure containing parts including welded joints and components. This includes reactors, towers, drums, heat exchangers, air cooled heat exchangers, and fired heater coils.

How does PMI help prevent flow accelerated corrosion in power generation facilities?

PMI prevents flow accelerated corrosion by verifying the correct percentages of key elements that determine material properties. This ensures materials with the right corrosion resistance are used in critical locations.

What handheld equipment is used to perform PMI on-site?

Portable X-ray emission or fluorescence spectrometers like Texas Nuclear 9266 or META scope are used for on-site PMI. These handheld XRF instruments provide direct reading of alloy grade and composition.

What industries require PMI for quality control and safety compliance?

PMI is critical in many industries including oil and gas, power generation, chemical, pharmaceutical, nuclear, aerospace, and metal fabrication. These sectors use PMI for pre-service and in-service inspection of critical components.

How is third party inspection integrated with PMI procedures?

Third party inspection agency protocols are followed during inspections and tests as per material requisitions. Construction contractors submit PMI procedures, including equipment specifications and reagent washing protocols.