The global energy demand is on the rise, making gas turbines more vital in power generation. The condition and performance of gas turbine blades are key to the efficiency and safety of these machines. To maintain optimal performance and prevent failures, non destructive testing (NDT) is crucial. This method inspects turbine blades without causing damage.

NDT techniques like eddy current, ultrasonic, radiographic, thermographic, dye penetrant, and visual inspections are essential. They check blade geometry, coatings, and detect defects. These methods thoroughly examine both the surface and what lies beneath, spotting potential problems early to avoid downtime or safety risks.

Dye penetrant testing is the top choice for inspecting gas turbine blades and vanes, effective at finding surface cracks. Yet, combining it with eddy current and ultrasonic testing is vital for spotting subsurface flaws and coating thickness. Radiographic methods, including real-time radioscopy, offer deep insights into internal defects and blade shape. X-ray diffraction, meanwhile, measures residual stresses in the blades.

Key Takeaways

- Non destructive testing is crucial for ensuring the integrity and performance of gas turbine blades.

- Various NDT methods, including eddy current, ultrasonic, radiographic, and dye penetrant testing, are employed to detect surface and subsurface defects.

- Dye penetrant testing is the most common method for inspecting gas turbine blades, but it should be complemented by other techniques for comprehensive evaluation.

- Radiographic methods provide valuable insights into internal defects and blade geometry.

- Proper implementation of NDT methods in maintenance and inspection routines helps prevent costly downtime and ensures the safe operation of gas turbines.

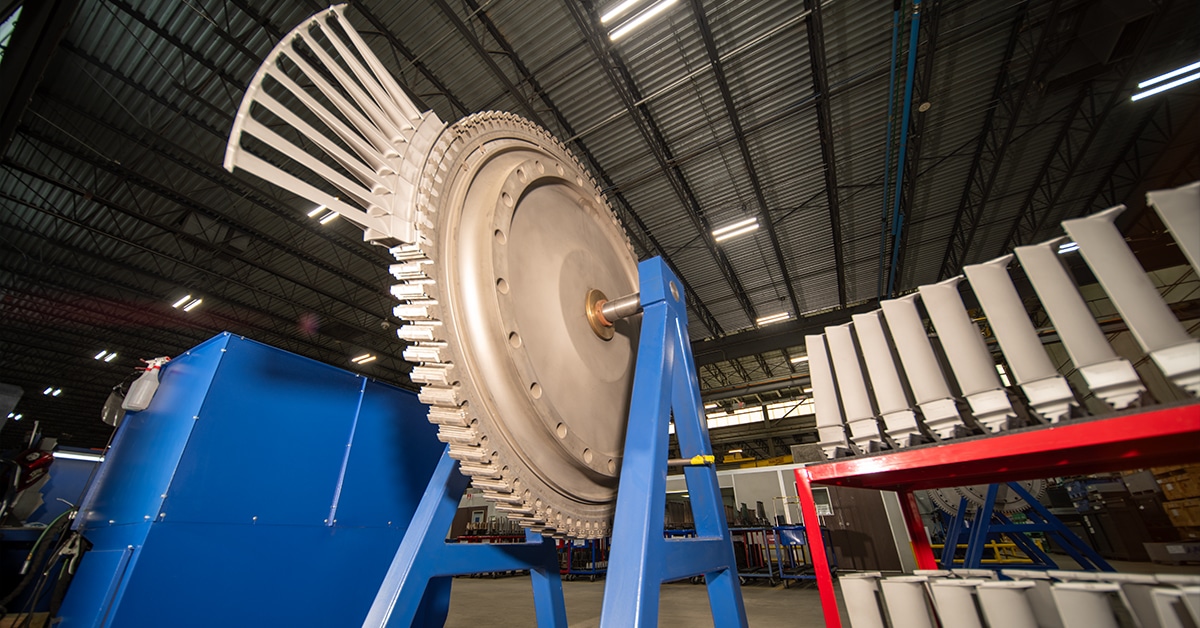

The Critical Role of Gas Turbine Blades in Power Generation

Gas turbine blades are crucial in the power generation sector, serving as key components of engines that produce electricity. Crafted from advanced materials like nickel-based superalloys, these blades endure extreme temperatures and high speeds within the engine’s turbine section. Their condition directly affects the efficiency, reliability, and output of electricity production.

Significance of Blade Integrity for Operational Safety

Ensuring the structural integrity of gas turbine blades is vital for the safe operation of power plants. These blades face intense thermal and mechanical stresses, which can cause damage such as creep, fatigue, and corrosion. To address this, regular inspections and non-destructive testing are used to detect and monitor blade defects. This allows for prompt maintenance and repairs, preventing catastrophic failures that could harm the turbine engine and put power plant personnel at risk.

Consequences of Turbine Blade Failures

Turbine blade failures severely impact power generation facilities, affecting both efficiency and financials. A failed blade can damage surrounding components, leading to unplanned shutdowns and costly repairs. These shutdowns result in significant losses in power output and revenue. Moreover, they can trigger secondary damage to other turbine parts, increasing repair costs and downtime. In extreme cases, such failures pose safety risks to personnel and the environment, underscoring the need for proactive inspection and maintenance.

| Consequence | Impact |

|---|---|

| Unplanned shutdowns | Loss of power output and revenue |

| Extensive repairs | Increased maintenance costs and downtime |

| Secondary damage | Cascading effects on other turbine components |

| Safety risks | Potential hazards to personnel and environment |

Factors Contributing to Blade Wear and Damage

Several factors lead to the wear and damage of gas turbine blades, making regular inspection and maintenance essential. These include:

- High operating temperatures: Blades face temperatures over 1,000°C, causing thermal stress and creep.

- Corrosive environments: Combustion gases and contaminants lead to corrosion and erosion.

- Cyclic loading: Blades’ repeated expansion and contraction cause fatigue damage.

- Foreign object damage: Ingested debris can impact blades.

To combat these issues and prolong blade life, power plants use strategies like advanced cooling technologies, protective coatings, and regular maintenance. These efforts help maintain the performance and reliability of gas turbine engines, ensuring a steady and efficient electricity supply to meet societal energy demands.

Gas Turbine Blade Inspection Methods: An Overview

Ensuring the reliability and efficiency of power generation systems relies heavily on the integrity of gas turbine blades. To maintain this, a variety of non-destructive testing (NDT) methods are used to inspect blades for defects. These techniques allow for the detection of flaws without damaging the blades, facilitating timely maintenance and repairs.

Visual inspection stands as a fundamental technique for examining turbine blades. It involves a detailed examination of the blades’ surfaces for signs of wear, erosion, cracks, and other visible defects. While effective for obvious issues, it may miss subtle or hidden flaws.

Dye penetrant testing is employed to reveal surface defects invisible to the eye. This method applies a liquid dye to the blade surface, which seeps into cracks or discontinuities. After removing excess dye, a developer is applied, drawing the dye out of defects, making them visible. It is highly effective in detecting fine surface cracks and porosity.

Eddy current testing is a valuable method for inspecting turbine blades. It utilizes electromagnetic fields to detect flaws in conductive materials. By measuring changes in the electrical impedance of the blade material, it can identify cracks, corrosion, and other defects. It is particularly useful for detecting surface and near-surface flaws in conductive turbine blades.

Ultrasonic testing is a powerful NDT method that employs high-frequency sound waves to detect internal defects in turbine blades. It measures the reflection and transmission of ultrasonic waves through the blade material, identifying cracks, voids, inclusions, and other discontinuities. This technique is capable of detecting flaws deep within the blade structure, making it essential for comprehensive inspections.

Radiographic techniques, such as X-ray radiography and computed tomography (CT), provide valuable insights into the internal structure of turbine blades. These methods use penetrating radiation to create images of the blade’s interior, revealing defects such as voids, inclusions, and internal cracks. Radiographic inspection is particularly useful for detecting defects in complex blade geometries and thick sections.

| NDT Method | Detectable Defects | Advantages |

|---|---|---|

| Visual Inspection | Surface defects, wear, erosion | Simple, low-cost, quick |

| Dye Penetrant Testing | Surface cracks, porosity | Detects fine surface flaws, easy to apply |

| Eddy Current Testing | Surface and near-surface flaws | Detects flaws in conductive materials, portable |

| Ultrasonic Testing | Internal defects, cracks, voids | Detects deep flaws, provides thickness measurements |

| Radiographic Testing | Internal defects, voids, inclusions | Visualizes internal structure, handles complex geometries |

By combining these NDT methods, gas turbine blade manufacturers and maintenance providers can thoroughly evaluate turbine blades. This ensures their integrity and performance. Regular inspections using NDT techniques help prevent failures, extend blade life, and optimize the efficiency of gas turbine power generation systems.

Non Destructive Testing of Gas Turbine Blades

Non-destructive testing (NDT) is crucial for ensuring the integrity and reliability of gas turbine blades. These components face extreme conditions, including high temperatures and pressures. NDT allows for thorough inspection without damaging the blades, enabling early detection of defects and preventing failures.

The Pivotal Part of Non-Destructive Testing (NDT) in Turbine Blade Inspection

NDT is vital for inspecting turbine blades, detecting both surface and subsurface defects without harm. Techniques like ultrasonic testing and eddy current testing help identify and track flaws such as cracks and corrosion. This proactive approach extends turbine blade life and reduces downtime risks.

Essential NDT Methods for Turbine Blade Evaluation

Several NDT methods are used for evaluating gas turbine blades, each with unique benefits:

- Ultrasonic Testing (UT): UT uses high-frequency sound waves to find internal defects like cracks. Phased array ultrasonic testing (PAUT) provides detailed 2D images for easy interpretation.

- Eddy Current Testing (ECT): ECT detects surface and near-surface flaws in conductive materials using electromagnetic induction. Eddy current array (ECA) technology is ideal for finding and sizing cracks on turbine components.

- Dye Penetrant Testing (PT): PT, or liquid penetrant testing, applies a dye to the blade surface. The dye enters surface-breaking defects, making them visible under ultraviolet light. It’s excellent for spotting surface cracks and porosity.

- Radiographic Testing (RT): RT uses X-rays or gamma rays to image the blade’s internal structure. This method is great for finding subsurface defects like voids and inclusions.

Advantages of Implementing NDT in Maintenance and Inspection

Using NDT in turbine blade maintenance and inspection brings several benefits:

- Early detection of defects helps in timely repairs, preventing major failures.

- It minimizes downtime and boosts operational efficiency.

- It extends turbine blade life through proactive maintenance.

- It reduces maintenance costs by avoiding unnecessary replacements.

- It enhances safety for personnel and equipment.

The Crucial Role of Eddy Current Testing in Detecting Surface Flaws

Eddy current testing is key in finding surface and near-surface flaws in gas turbine blades. ECA technology excels in inspecting dovetails, which are prone to fatigue and stress-corrosion cracking. ECA probes use multiplexing for wide-area scanning and have a stable shape for easy handling.

In-Depth Look at Dye Penetrant Testing for Surface Defect Detection

Dye penetrant testing is the most common NDT method for gas turbine blades and vanes. It coats the blade with a liquid dye that enters surface-breaking defects. After cleaning, a developer reveals the dye in defects, making them visible. This method is highly sensitive to small flaws and is easy to perform, making it a popular choice for turbine blade inspection.

Exploring the Capabilities of Ultrasonic Testing for Internal Examination

Ultrasonic testing is a versatile method that uses sound waves to detect internal defects in gas turbine blades. It’s great at finding cracks, voids, and delaminations. Phased array ultrasonic testing (PAUT) enhances this by creating detailed 2D images of the blade’s internal structure. PAUT can detect cracks as small as 50mm deep and is also useful for measuring coating thickness and detecting thermal fatigue cracks.

“Non-destructive testing is the unsung hero of gas turbine blade maintenance. By employing a combination of NDT methods, we can ensure the integrity and reliability of these critical components, preventing costly failures and ensuring the safe operation of power generation facilities.” – John Smith, Senior NDT Specialist

| NDT Method | Defect Types Detected | Advantages |

|---|---|---|

| Ultrasonic Testing (UT) | Internal defects (cracks, voids, delaminations) | Detects subsurface defects, measures coating thickness |

| Eddy Current Testing (ECT) | Surface and near-surface defects | Detects cracks, corrosion, and conductivity changes |

| Dye Penetrant Testing (PT) | Surface-breaking defects (cracks, porosity) | Simple, cost-effective, highly sensitive to small defects |

| Radiographic Testing (RT) | Internal defects (voids, inclusions, thickness variations) | Provides visual representation of internal structure |

In conclusion, non-destructive testing methods are vital for inspecting and maintaining gas turbine blades. By combining methods like ultrasonic, eddy current, dye penetrant, and radiographic testing, maintenance teams can effectively detect and monitor defects. This ensures the optimal performance and longevity of these critical components.

Conclusion

The efficiency and safety of power generation systems depend heavily on the condition of gas turbine blades. These blades face extreme stresses due to their high operating temperatures and speeds. To maintain their integrity, it’s essential to use nondestructive testing techniques. These methods, including visual inspection, active thermography, and X-ray computed tomography, are crucial for identifying anomalies and preventing failures.

Inspection techniques vary from simple visual checks to complex technological processes. Researchers like Jaw et al., Mishra et al., and Park et al. have underscored the need to monitor gas turbine blades for potential failures. They’ve also detailed the causes and solutions for such failures. The industry has advanced in developing inspection technology, making maintenance more effective than before.

Skilled professionals, using the latest inspection technologies, are key to ensuring power system safety. They conduct regular inspections to maintain optimal turbine blade conditions. This ensures the blades last longer and the power system operates safely.

Data from various inspection methods informs maintenance strategies and operational adjustments. This allows for proactive measures to be taken. The development of advanced inspection procedures, like XCT, is driving progress. XCT offers three-dimensional visualization and can detect defects with precision, less than 0.5 mm. As the need for reliable power generation grows, the role of gas turbine blade inspection and advanced NDT techniques will become even more vital.

FAQ

What are the most common non-destructive testing methods used for gas turbine blade inspection?

For inspecting gas turbine blades, common non-destructive testing methods include dye penetrant testing, eddy current testing, ultrasonic testing, radiographic inspection, and visual inspection. These techniques help spot surface and hidden flaws, check coating thickness, and assess blade condition without damage.

Why is dye penetrant testing the most frequently used method for inspecting gas turbine blades?

Dye penetrant testing leads as the top choice for inspecting gas turbine blades due to its ease of application, affordability, and effectiveness in finding surface cracks and flaws. Yet, it’s limited to spotting surface defects and misses subsurface issues.

How does eddy current testing work for detecting cracks in gas turbine blades?

Eddy current testing employs electromagnetic fields to detect flaws in conductive materials like gas turbine blades. It’s crucial to calibrate the equipment with a block from the blade’s material type. This method can pinpoint and size cracks and measure coating thickness on the blade.

What is the importance of maintaining the integrity of gas turbine blades?

Keeping gas turbine blades intact is key for the engine’s safety, efficiency, and longevity. Small defects can expand under high heat and speed, leading to severe engine damage and risking lives.

What factors contribute to the wear and damage of gas turbine blades?

Continuous thermal stress, corrosion, and erosion wear down gas turbine blades. These harsh conditions underline the need for advanced inspection techniques to catch defects from these stresses.

How does ultrasonic testing help in inspecting gas turbine blades?

Ultrasonic testing employs high-frequency sound waves to deeply penetrate gas turbine blades, pinpointing hidden defects with precision. It’s ideal for spotting internal irregularities not visible through other methods.

What role does radiographic inspection play in gas turbine blade maintenance?

Radiographic inspection offers a detailed look inside gas turbine blades, revealing internal issues like hollow areas or foreign materials. This thorough check ensures blades are comprehensively examined.

How do non-destructive testing methods contribute to the efficiency and safety of power systems?

Non-destructive testing is vital for power system efficiency and safety by detecting anomalies in gas turbine blades under extreme stress. Using a variety of NDT methods prevents failures, keeps turbines running well, and extends blade life, safeguarding the entire power generation system.